Stereolithography (SLA)

Stereolithography (SLA)

What is Stereolithography (SLA)?

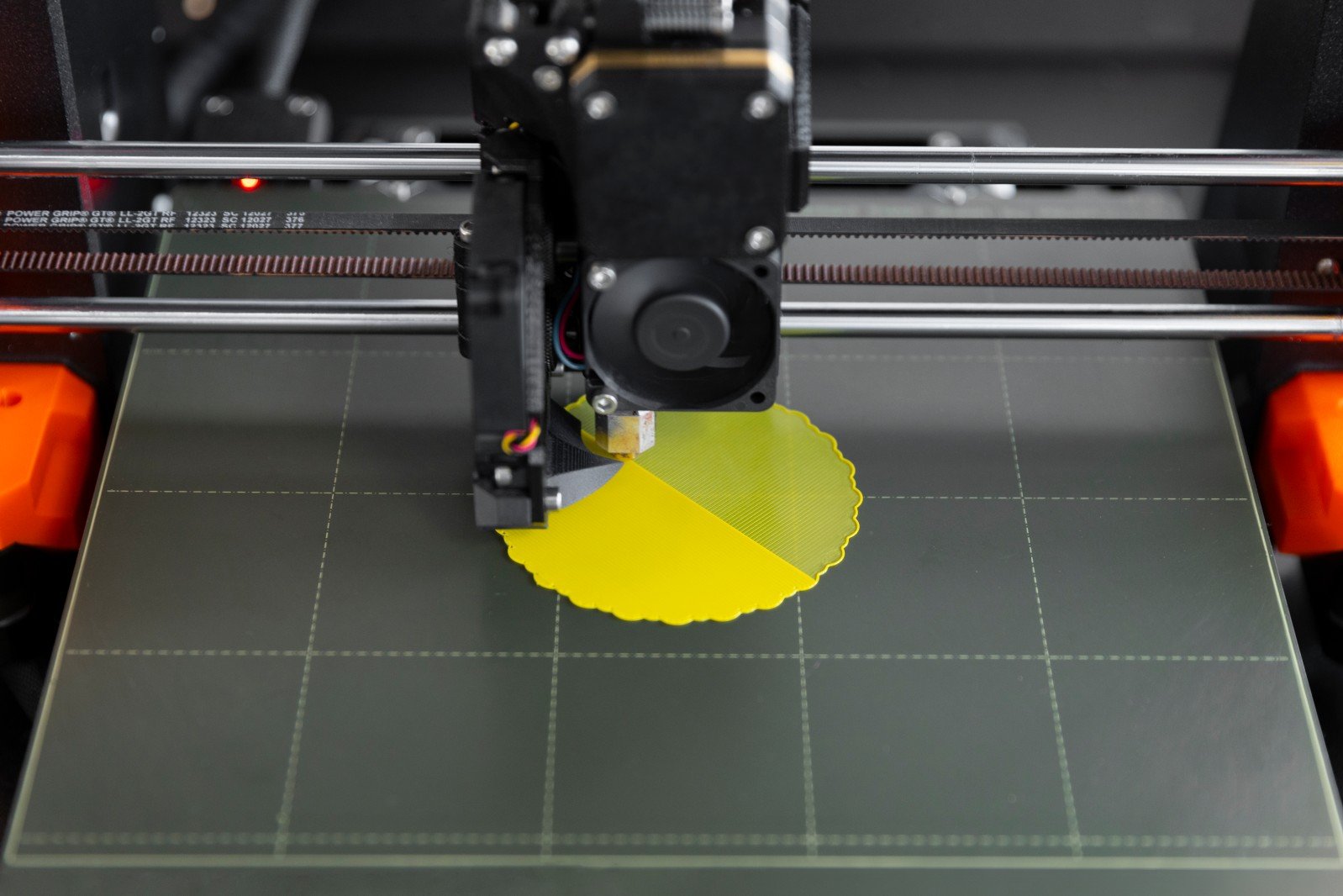

Stereolithography, also known by its shortened form SLA, is one of the 3D printing methods most in favor. Stereolithography is considered high-precision and great detail. The innovative process uses a laser beam focused on a reservoir of liquid resin to cure it and build the object into solid form, layer by layer. As the laser goes over the top of the resin, it hardens targeted areas of the resin, slowly developing a three-dimensional figure. SLA is specially famous for models with surface finishes and designs and is widely used in multiple industries.

Benefits of Stereolithography (SLA)

SLA comes with several noteworthy advantages:

- High Precision: The laser used in SLA comes with wonderful precision, meaning it is really fine in detail, so the smallest details in the drawing are captured very well. Thus, it is perfectly suited for industries that emphasize high quality.

- Smooth Surface Finish: Parts created with the use of SLA are usually smooth, so no heavy post-processing is required. Such quality is very useful for visual models and products intended for client presentations.

- Material Variety: SLA Resin materials by SLA come in different types, varying in their strengths and elasticity levels or temperature resistance. All these features allow choosing resin material for specific projects.

- Speed: SLA can be able to produce highly detailed and time-efficient models, making it imperative for high-speed businesses. This allows the companies to reduce product development cycle time, thereby speeding up getting products into the market.

FAQ's

If this is your first time seeking an SLA 3d Printing service, you likely have some questions. Read on to learn more!

SLA has been generally applied in making prototypes, detailed designs of jewelry, dental models, and functional parts in numerous industries.

SLA is renowned for accuracy and high-end surface finish compared to almost any other method, such as FDM (Fused Deposition Modeling), which could be faster in much larger parts but does not have the same resolution.

This resin model may not be suitable for very large parts or perhaps even more any application in extreme durability since the resin probably may not withstand high-impact conditions better than some other materials.

LET'S CONNECT !!!

Contact Maadhu creatives & We’re here to help you grow your business.