Piping Model-Making

Basics of Piping Model-Making

Piping models are one of the most essential parts of any structural design, be it residential, industrial or commercial projects, and need to be executed with great precision and care.

This piping system can be used to transport solid, liquid or gaseous materials such as air pressure, heat, oil, steam water, chemicals, and so on.

Piping models are considered the most complex of models as they add to the smart design aspect of any structure. Most of the time, these pipelines must be hidden while still functioning properly.

Types of piping models

1. Conceptual design model

Conceptual design model provides the pipeline mapping during the design phase itself (that is the initial stage) to get a clear understanding of design viability or correction of flaws in intended design. This kind of model is typically low cost and in its most basic form since it aids in improving the design after a clear understanding has been gained.

2. Working model

The working model is built by the companies after an understanding is gained using conceptual design. It is built when the design experts and engineers want to understand how entire piping system project works. This model will help boost several significant design-related data, such as:

- Length and ideal pipe size required for different types of material that will pass through the pipes

- Geometric alignment (i.e.) the ideal distance between the curves required in the flow of material

- Adequate utility design to avoid clashes in pipe design

- Placement of pipes and structures around them

- Depths, gradients, flows, capacities, and velocities for different pipe sections,

- Ability to check the flow and conduct stress analysis, etc.

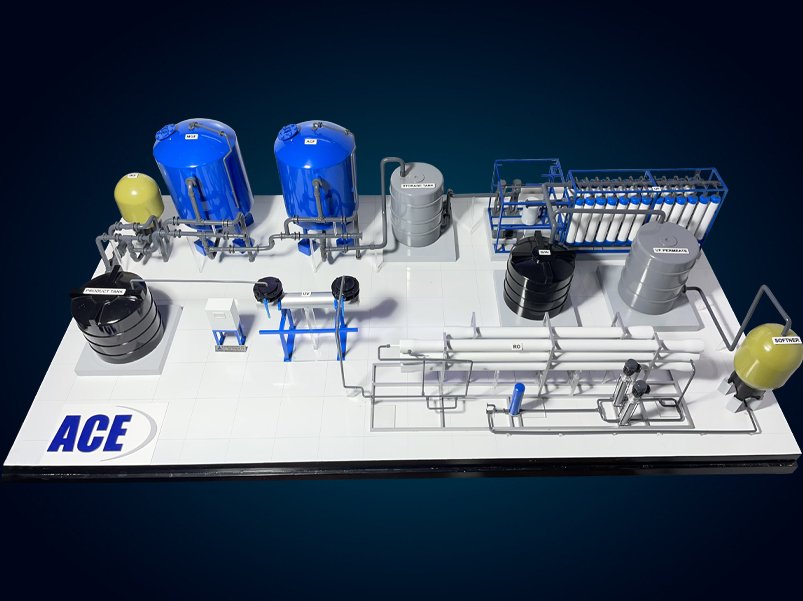

3. Presentation model

Presentation model type is solely used for presentation purposes in exhibitions, trade fairs, offices, courts, etc. It helps in giving a visual representation of the suitable project design with appropriate placement of all types of pipes in and around the project, the route layouts, etc.

4. Cut or cross-section model

Cut section model (also called a cross-section model) type is used to highlight the internal elements of the project while maintaining the outer look. The model is analyse to illustrate a particular section that has the vital piping connections, or a section of the pipe is left open to showcase the actual flow of the material. This makes it simpler to understand.

Ten common Industries where Piping design and models play a vital role:

Piping models are used as a prototype of pipe layout in industries that have large piping infrastructure and where pipe connectivity plays a important role in process flow. It forms basis of verifying the movement of delicate factors like air pressure, heat, steam, oil, etc. It is widely used in industries such as:

- Chemical

- Oil and Gas

- CNG-LPG plants

- Petroleum refineries

- Pharmaceuticals

- Water Resource Management (water, storm water, or sewer pipes)

- Power plants

- Waste Management

- Heavy-scale Industries (Iron and Steel)

- Pipelines in residential projects

Material used for building Piping models

The following are some of the most commonly used materials for piping model-making:

- Industrial grade acrylic

- Cardboard

- Metal (rods, screws)

- Glass

- PVC (pipes)

- ABS rode

- High impact polystyrene resin (HIPS resin)

- PLA plastics – 3D printer material

When choosing these materials, two variables are taken into account: the model’s size and degree of intricacy.

Technology in Piping models

Utilizing 3D technology, pipe model making has improved thanks to technology advancements. Such models give a more precise representation of design and curves of each pipe and offer a cleaner cross-section design display. However, a few pipe model makers still using conventional methods in creating the model.

Uses of Piping model-making:

- To depict the design, placement, and working of piping structure in a project.

- To achieve proper/correct utility mapping during design phase of pipeline.

- To ascertain optimized material movement design

- To get all required design calculations correct especially for movement of sensitive material like heat, pressure, etc to avoid any fatal incidents.

If you are looking for a reliable scale model-maker for your upcoming requirement, you can surely rely on the team of experts at Maadhu Creatives. Maadhu Creatives is one of the top piping model-making companies in India, based out of Mumbai. They have extensive experience and in-depth knowledge in piping model-making and will guide you and work along with you for all your model-making requirements.

Rate this post