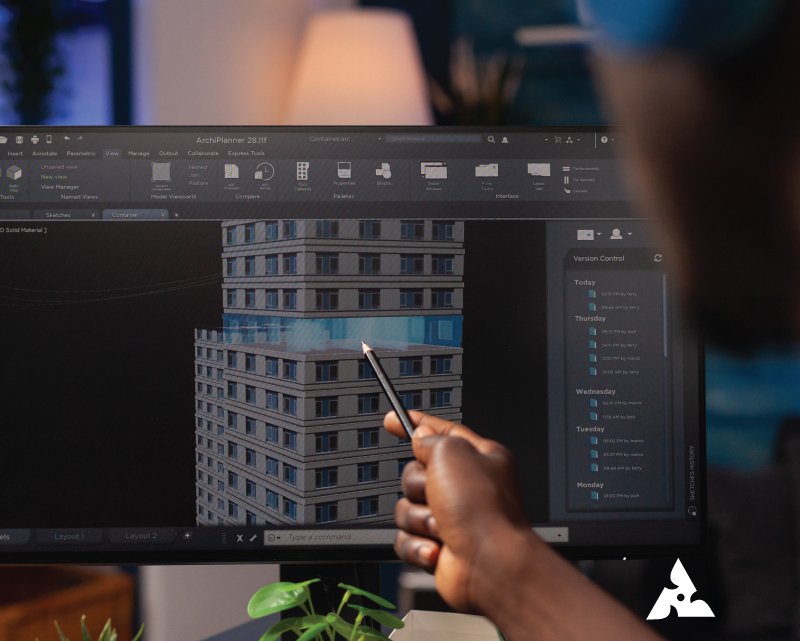

Industrial Model Making

Industrial Model Makers / Factory Model Makers /Factory model / Ware house Model Making / Industrial Scale Models

An object should be judged by whether it has a form consistent with its use. – Bruno Munari

"Behind every product, there's a story of dedication, precision, and the relentless pursuit of excellence. That story belongs to the industrial model."

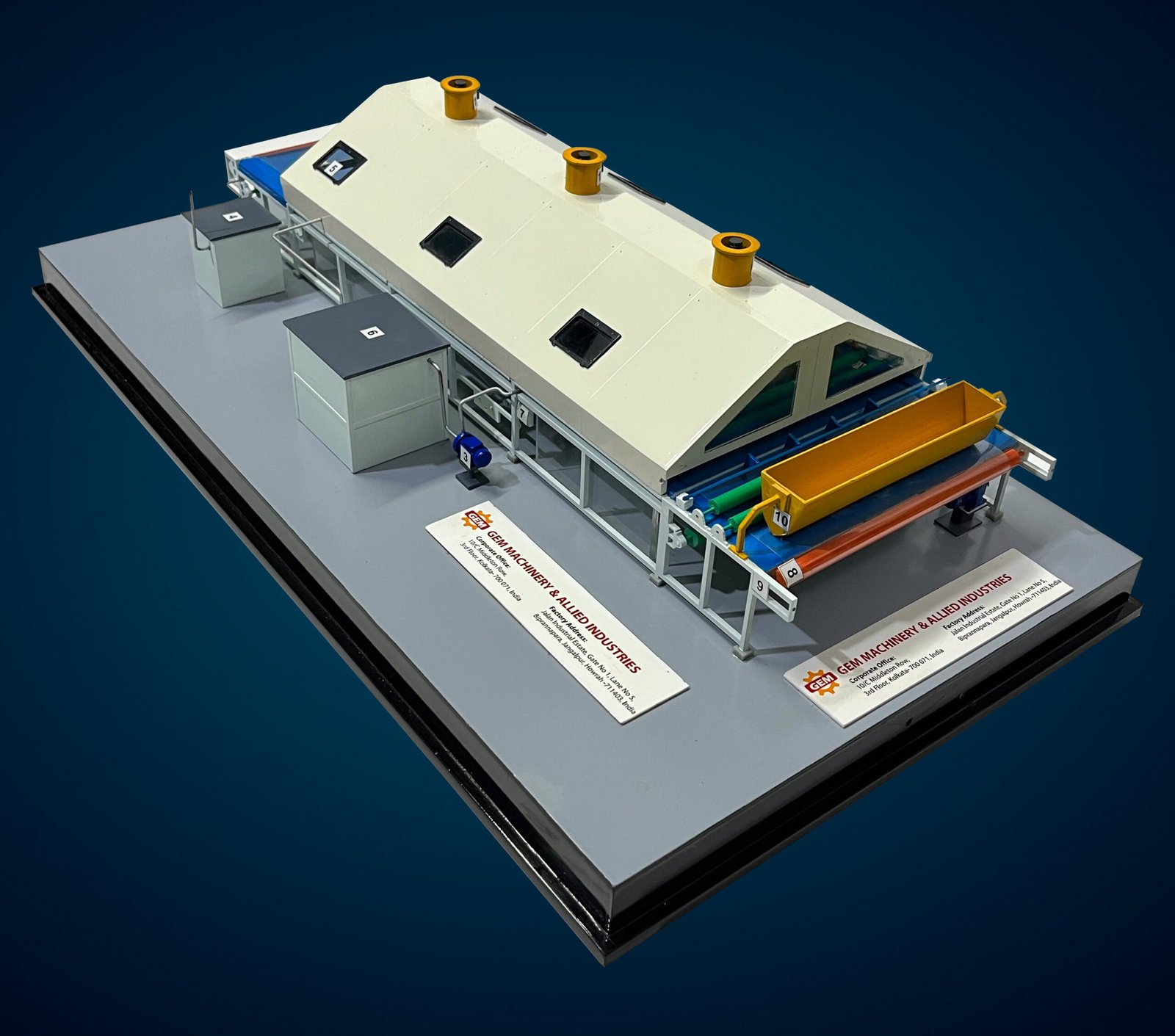

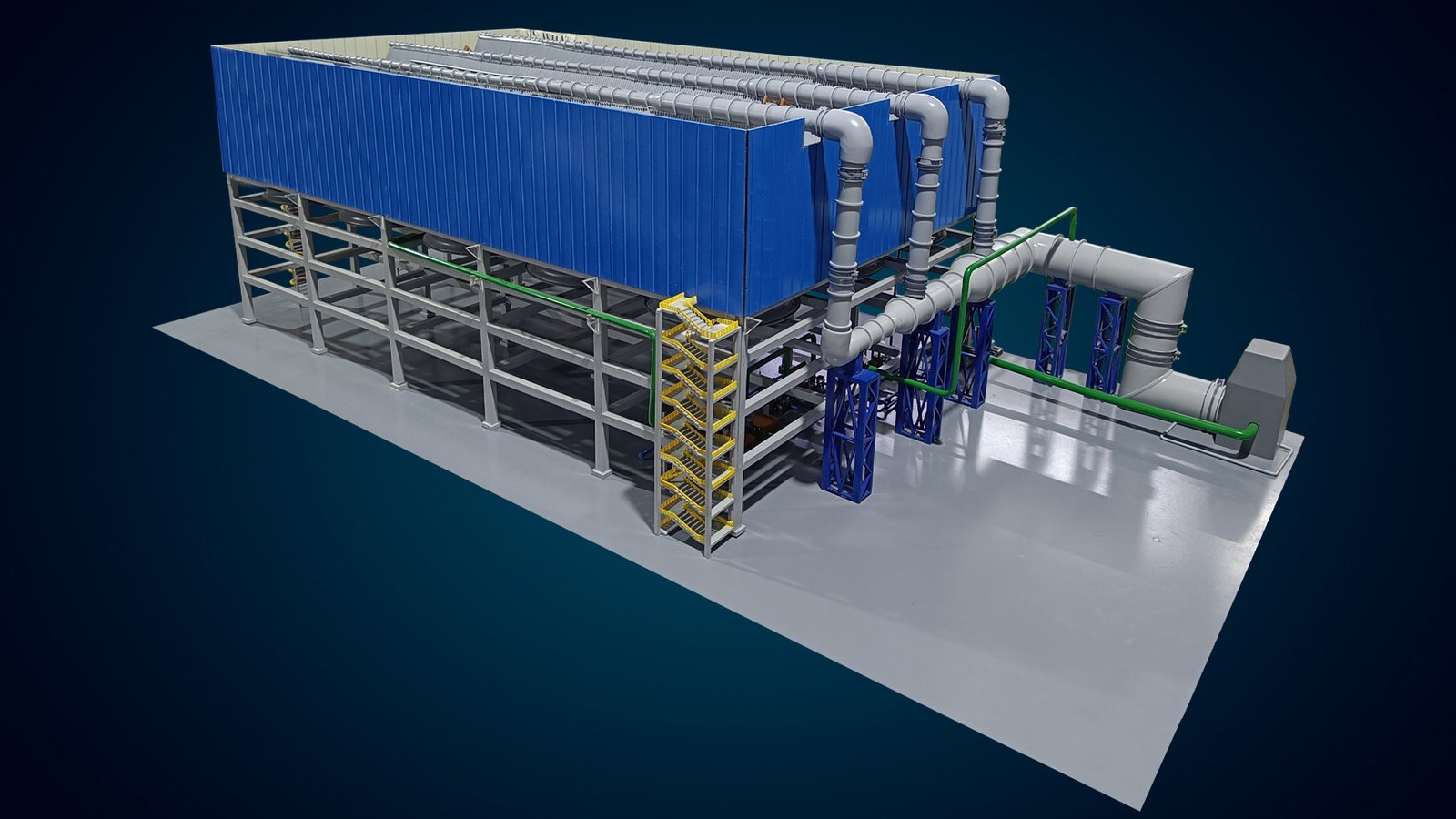

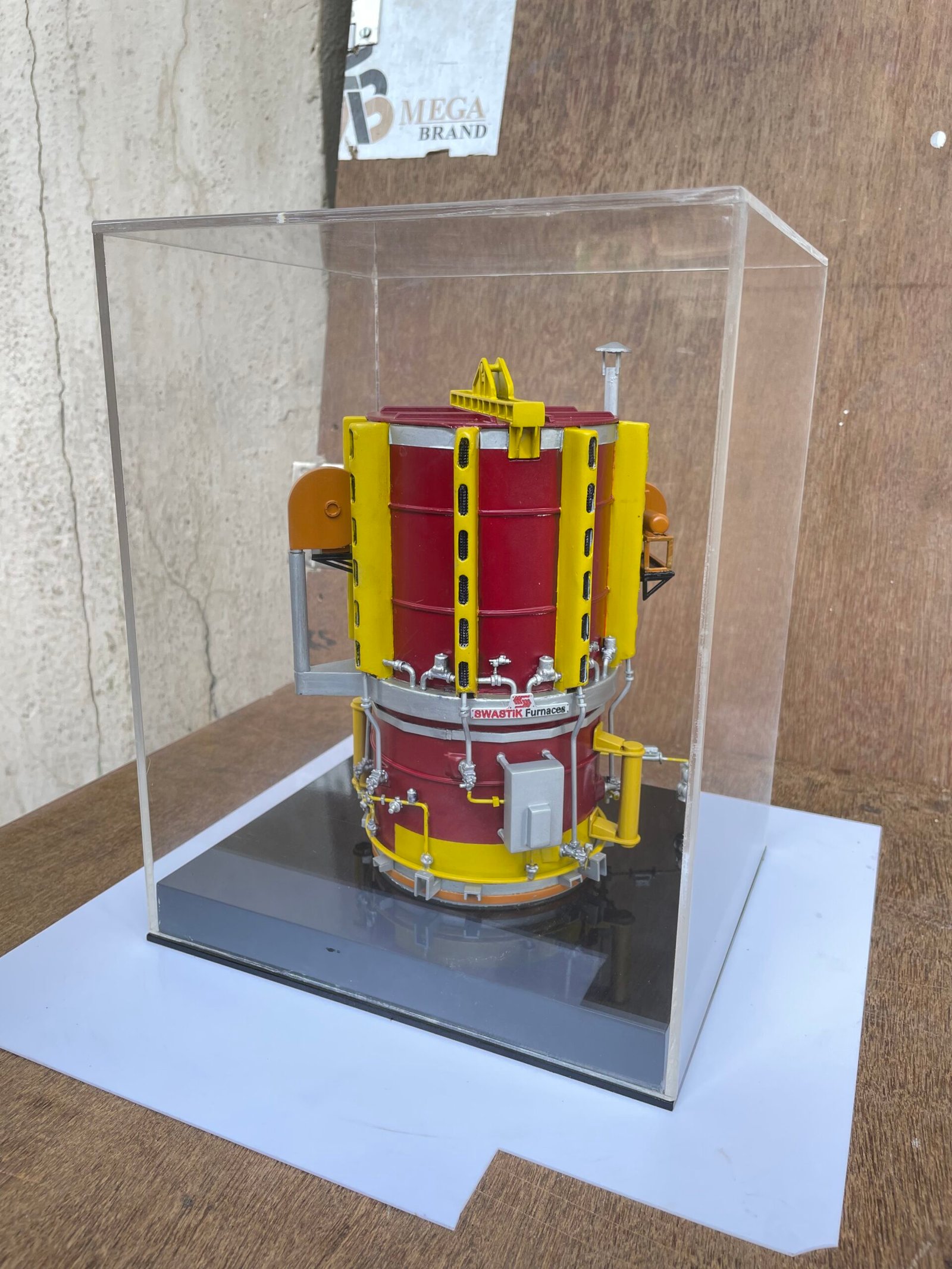

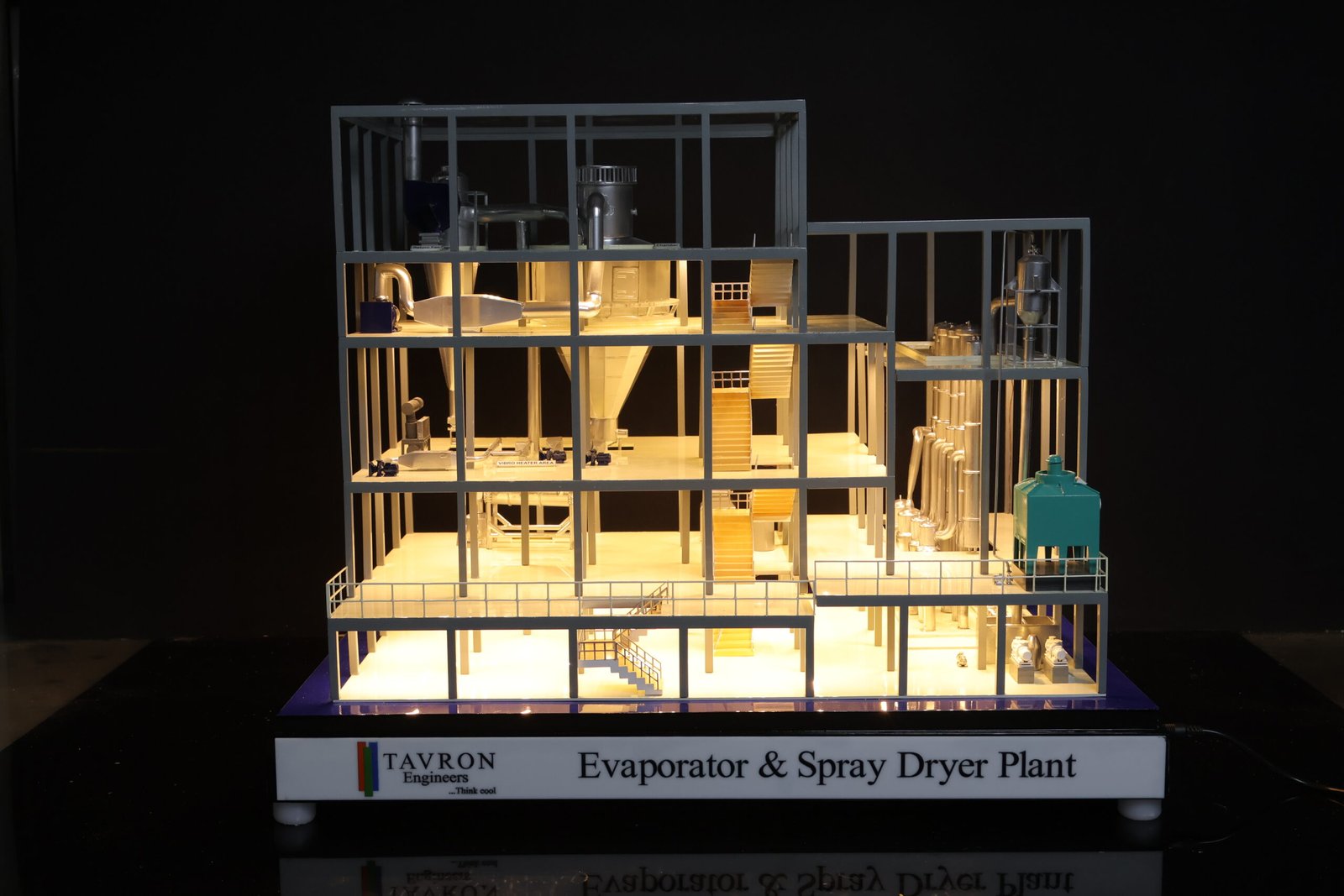

Industrial models are intricate three-dimensional representations of industrial designs, processes, and products.

They offer a comprehensive replica of every aspect of their physical site within a single, cohesive framework, providing a holistic view for analysis and planning.

What is the Meaning of Industrial Model Making?

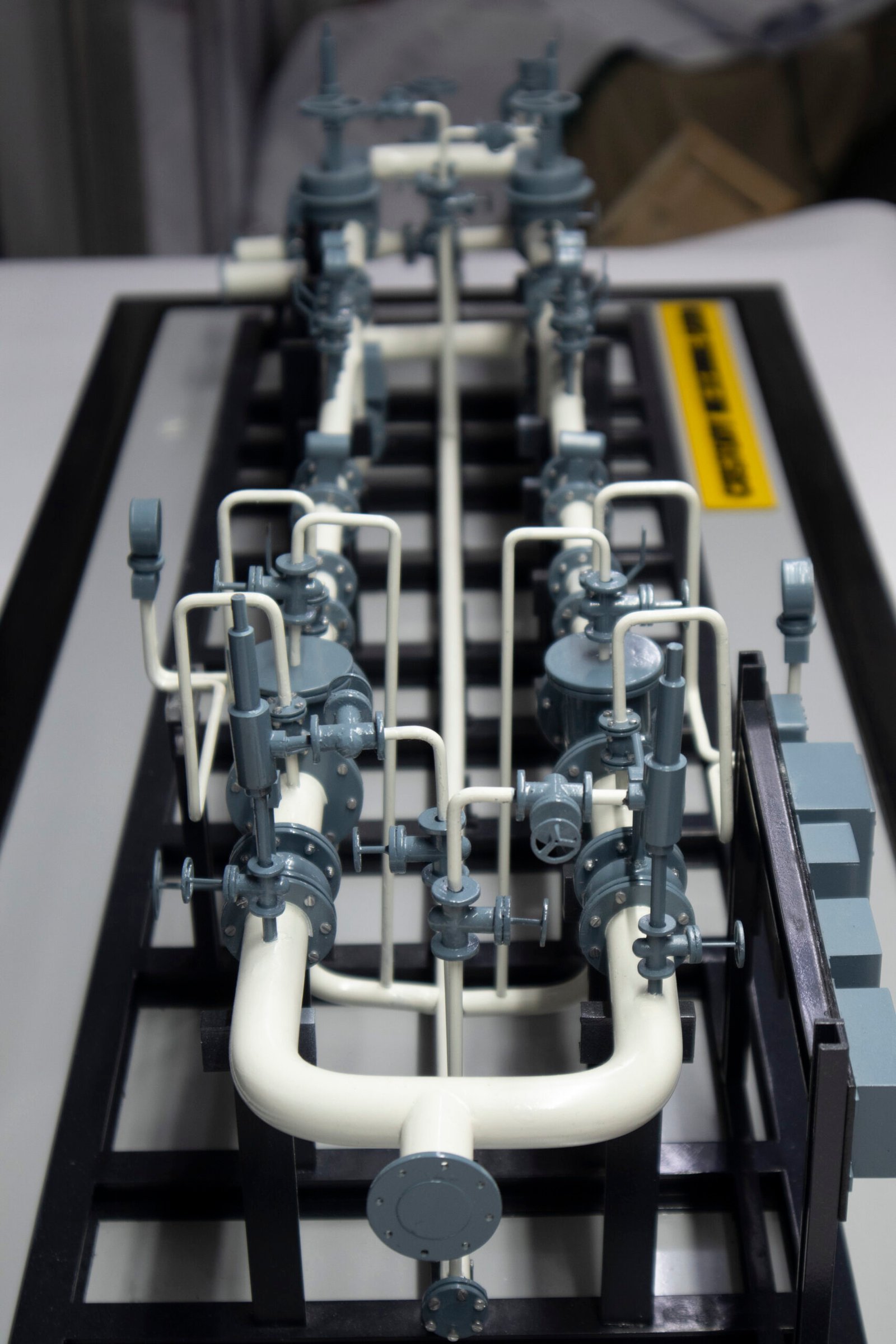

Industrial model-making is a technique of developing replicas of a product, structure, or system that are used in industries. These models are useful to the designers, engineers, and other stakeholders in the project because they allow them to visualize and comprehend structures before they are created as real structures. In fact, the applications of industrial models are numerous, and they include things such as a new product design, constructing a building, or even an engineering design. It can be manufactured using plastic material, metal, or wood, among others, depending on what is required.

Benefits of Industrial Model Making

- Better Visualization: This type of modeling has the advantage that everyone is able to see what the final product or structure will be like. A physical model offers the benefit of identifying various difficulties in the design and enhancing the general appearance.

- Clear Communication: Models are used by teams to explain or describe something in broad and general terms. They use it during the meeting and presentations to explain different concepts, which makes people understand the project.

- Cost Savings: Spending money on a model could end up saving a lot more down the line. In this way, companies can identify design problems before the physical product is created, so that there is no waste of money when the product is realized.

- Prototyping: Industrial models are largely useful because they can be used to produce small copies quickly, and businesses can make adjustments before going to mass production. This leads to improved products being produced since they meet customer needs and wants.

- Marketing Tools: Indeed, when it comes to marketing, models can be oh-so useful too. It presents products as they are and helps in attracting investors or customers.

- Training and Education: They are also very useful in the training of the models especially within the industrial sectors. This way it is easier for new employees to be trained regarding specific systems and processes in a hands-on approach.

FAQ's

If this is your first time seeking an industrial scale model-making service, you likely have some questions. Read on to learn more!

Model making in industrial design involves creating physical prototypes or scaled representations of products to visualize and test design concepts. These models help designers evaluate form, function, and aesthetics, allowing for refinement before mass production. It’s a crucial step in ensuring that the final product meets both design and user requirements.

1. Visualize Complex Systems: Provide a tangible representation of industrial processes, equipment, or facilities to better understand their layout and operation.

2. Enhance Communication: Aid in conveying design concepts to stakeholders, clients, and team members, making it easier to explain and discuss ideas.

3. Facilitate Planning: Assist in planning and decision-making by offering a clear view of how components interact within the system.

4. Support Training: Serve as educational tools for training personnel on equipment operation, safety procedures, and maintenance.

5. Prototype Testing: Enable testing and refinement of designs before full-scale production, reducing risks and costs.

1. Define the Scale: Choose a scale, such as 1:50 or 1:20, based on the size of the space and the level of detail required.

2. Gather Materials: Use materials like foam board, cardboard, balsa wood, or 3D printing for walls, floors, and furniture. Paper or plastic sheets can represent windows and other transparent elements.

3. Create Floor Plan: Draw the floor plan to scale on a base material, marking walls, doors, and furniture placements.

4. Build the Structure: Cut and assemble the walls, doors, and windows according to the floor plan. Ensure accurate alignment and proportions.

5. Add Interior Elements: Construct and place scaled-down furniture, fixtures, and other interior elements, paying attention to detail.

6. Finish with Details: Add textures, colors, and lighting to enhance realism, using paint, fabric, or printed materials.

7. Assemble and Review: Put all components together, review for accuracy, and make adjustments as needed.

8. Presentation: Display the model on a base, possibly with accompanying notes or a presentation board to explain the design.

Depending on the project we work on, we have different materials, such as plastic, metal, wood, and resin, among them.

Absolutely! Our key strength lies in our ability to create bespoke models in line with the client’s requirements.

LET'S CONNECT !!!

Contact Maadhu creatives & We’re here to help you grow your business.