The True Cost of 3D Modeling: A Comprehensive Breakdown

Table of Contents

In today’s highly digital world, 3D modeling has found its place as an important core for industries such as architecture and product design, entertainment, and virtual reality. More and more organizations and individuals are looking into expressing ideas through 3D models; people would often ask that one basic question: What is the true price of a 3D model? The truth of the matter is, it is not that simple. The price is affected by quite a few elements. I will thoroughly explain this through this blog, focusing primarily on architectural models and the printing process. By the end of this article, you will understand what determines the cost of 3D models and how to ensure that navigation through the complex landscape goes by accordingly.

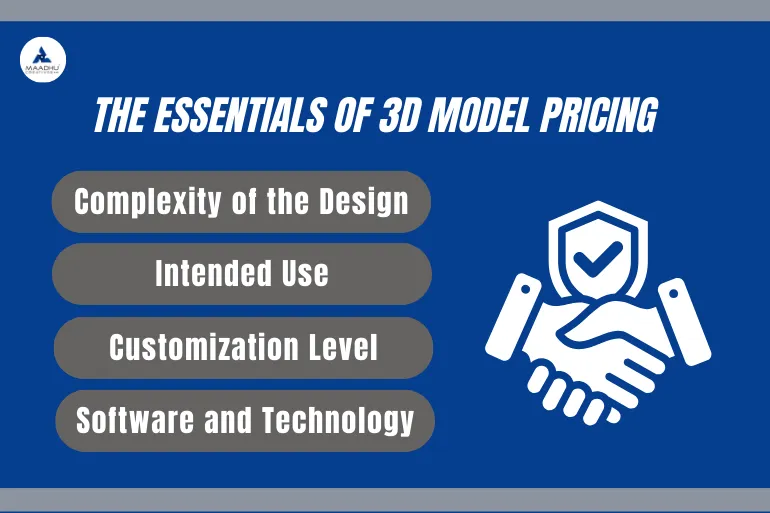

The Essentials of 3D Model Pricing

1. Complexity of the Design

The complexity of the model is one crucial determinant of the cost to be put on a 3D model. One can easily complete simple designs within hours, similar to a simple geometric shape. For some models, hours or even days will pass without it being completed, when experts finish some within a few hours and others take months to complete.

Here are a few thoughts on complexity:

- Geometric Complexity: Models with complex shapes or details tend to take longer to construct.

- Functional Elements: Models designed for a specific function, like animation or interaction, are likely to need more planning and execution.

2. Intended Use

The cost of the model depends completely on its usage. Different uses require a different degree of detail and precision.

- Marketing and Presentations: It would probably require high-grade visuals for marketing and presentations, meaning that more money would be thrown around in terms of detail and actuality.

- Prototyping: If the model has to be used for prototyping, then it has to be functional and cost more as more design aspects have to be addressed.

3. Customization Level

Another important characteristic is customization. Customizing a model to suit certain needs often costs more.

- Client Requirements: Those models that needed to be fitted into some set of guidelines or branding elements would take longer to perfect.

- Revisions: The more revisions a client requests, the higher the costs can escalate.

4. Software and Technology

The choice of software and technology used for modeling has a great influence on determining costs. Premium software usually entails licensing fees that are added to costs. More fundamentally, certain specific effects or functionalities may require the use of specially designed software for specific projects.

3D Printing Costs for Architectural Models

The advent of 3D printing has revolutionized how architectural models are created. Nevertheless, there are some variables that still determine the total cost for 3D printing:

1. Material Selection

The kind of material chosen for the process determines the cost the most. The materials typically employed are:

- Plastic: These are less costly and widely used for small models.

- Resins and Metals: Such types can provide better quality along with a longer life cycle but are generally much more costly.

2. Model Size and Scale

Another cost determinant of the model is its size. A larger model consumes more material and will take a much longer time to print, thus directly adding to the overall cost:

- Small Models vs. Large Models: A small model may be a few dollars or less than a hundred, whereas a large, detailed model easily runs into hundreds or thousands of dollars.

3. Detail Level

The detail level again may mirror traditional modeling: In 3D printing, the level of detail can push the cost up. Models that require complexities in the printing technique or print run raise the cost.

- Layer Height and Resolution: Models with thicker layers and finer resolutions are costly to print.

4. Post-Processing Requirements

Most 3D-printed models require post-processing, which significantly contributes to costs. This can be as basic as sanding, painting, or assembly. Each of these processes takes time and resources and adds to the final price.

How Much Does It Cost to Create a 3D Model?

While an accurate cost of a 3D model is difficult to establish with so many variables, the following list outlines common costs that go toward it:

1. Labor Costs

Labor usually accounts for the largest share of the bill. The quality of your designer and the experience he has will significantly impact the cost.

- Experienced Designers: More experienced designers mean higher charges but work out best in terms of quality and efficiency.

- Location Influence: Geographic location may also be involved. Designers in urban areas are likely to cost more than those located in rural areas.

2. Complexity of the project

As stated earlier, the complexity of the project will largely influence cost; complex projects may call for more resources, tools, and time to execute, which may consequently result in increasing prices.

3. Duration

The time crunch also affects the expenses. Projects done in a hurry come at a premium cost. If you need a model in a hurry, be prepared to pay extra for expedited services.

Comparing 3D Models with Traditional Models

1. Cost-Effectiveness

Second, while the lower first cost might be offered by traditional models, traditional models end up more costly in labor and material over the long run due to longer production runs and less flexibility in revisions.

2. Accuracy and Detail

3D models are much more precise and detailed as opposed to what is possible with conventional methods. This is all the more important if the function of a presentation or even functional prototypes is involved.

Making Informed Decisions: Assessing Your Needs and Budget

1. Know Your Budget

Actually, it pays quite a lot to pre-plan the budget for your 3D modeling project. Knowing what features and details are important for your model can make decisions easier to streamline.

- Identify Non-Negotiables: Determine which aspects of the model are crucial for your project and which aspects may be adjusted according to budget constraints.

2. Research and Consult Professionals

Consulting 3D modeling professionals will make you aware of the requirements of your project and let you know how much it would cost roughly:

Free Consultations: Most 3D modeling companies have a free consultation like Maadhu Creatives, where they sit and discuss the scope of the project, along with giving you an estimation. This will enable you to get an idea of the costs involved without any commitment.

The Importance of Quality in 3D Modeling

But whereas budget is critical, the quality of the 3D model cannot be sacrificed. In fact, good quality models may mean a lot, for marketing and presentations as well as for prototypes. On the other hand, poorly done models may misrepresent your vision and waste resources.

How to Find the Right Balance

Cost vs Quality Balancing is of paramount importance. Here are some ways to ensure that you spend the best amount of money for your investment:

- Assessment of the Service Provider: Research and know everything about the artists or companies whose work will be used. Their portfolio can give you an idea of what you can expect as far as quality is concerned.

- Long-Term Value: Such investment comes in the form of 3D modeling. As far as cost goes, a model with high quality will be costly initially but can save you time and resources in the long term.

Conclusion

Those elements that will determine the cost of a 3D model can help guide the proper decision-making on your project. While the actual pricing can be greatly different with plenty of factors, paying attention to the aspects of complexity, use, and customization would make you plan ahead properly.

If you have questions or just want to talk through your project in further detail, we’re here for you. The best source of personalized guidance that you can directly apply to your needs can be found by consulting professionals for sure. Find the very best outcome for your 3D model project by talking it over with someone today!

FAQs About the cost of a Model

Costs differ in various factors depending on design complexity, use, flexibility in customization, and software or technology used in modeling.

General cost depends upon the choice of materials used, model size, level of detail, and post-processing. Size and complexity determine cost, and the larger and more complex the model, the costlier it is.

Sometimes you can even negotiate to get a less expensive version by simplifying the design or limiting amendments in your 3D model. Talking about your budget before helps the designer find cost-effective options.

Investment in quality delivers closer precision and better presentation that would ensure your project would effectively deliver the right objectives, thereby saving you money in revisions or rework later.