Engineering Model Making

Engineering Model Makers / Machine Model Makers /

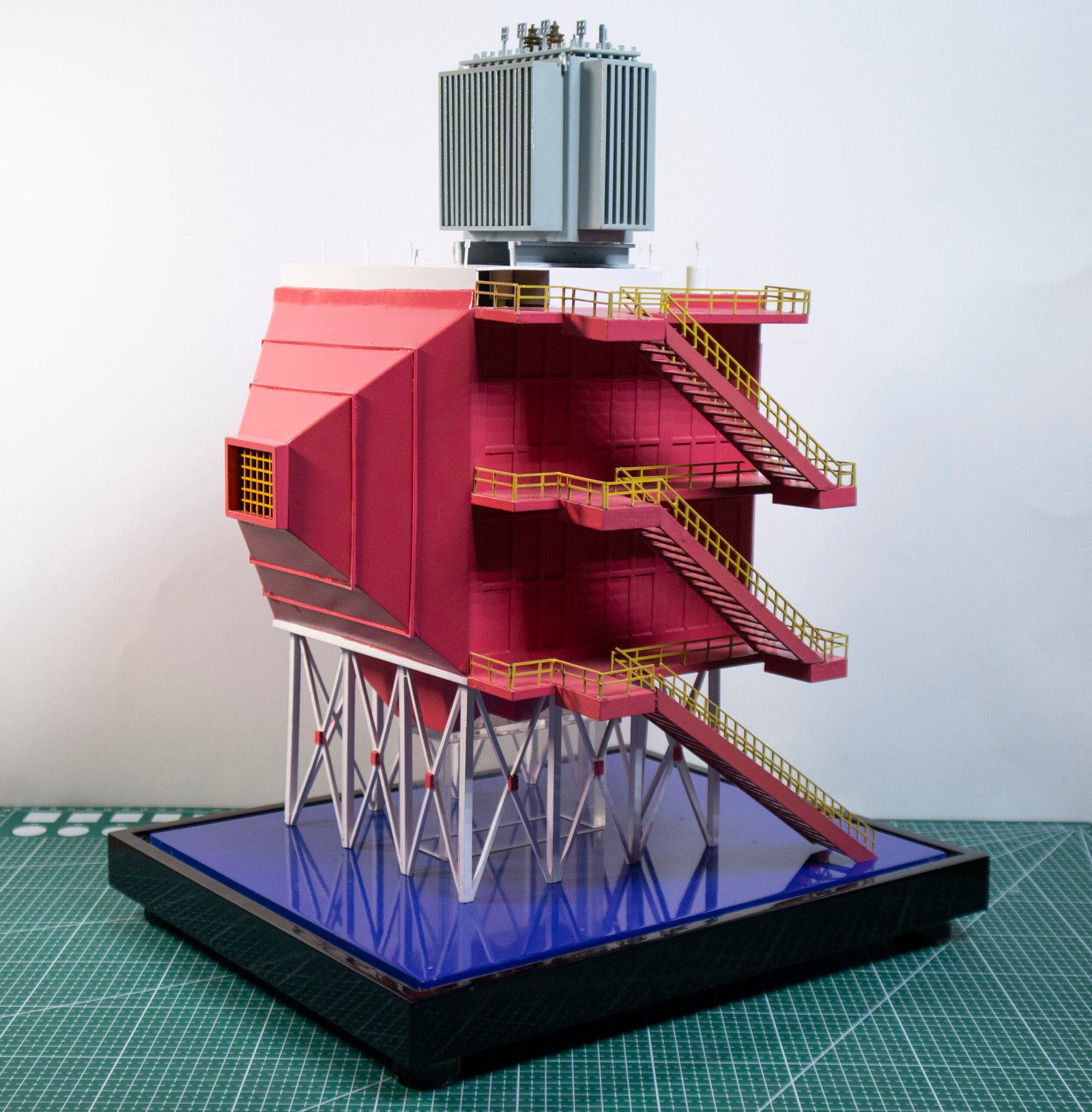

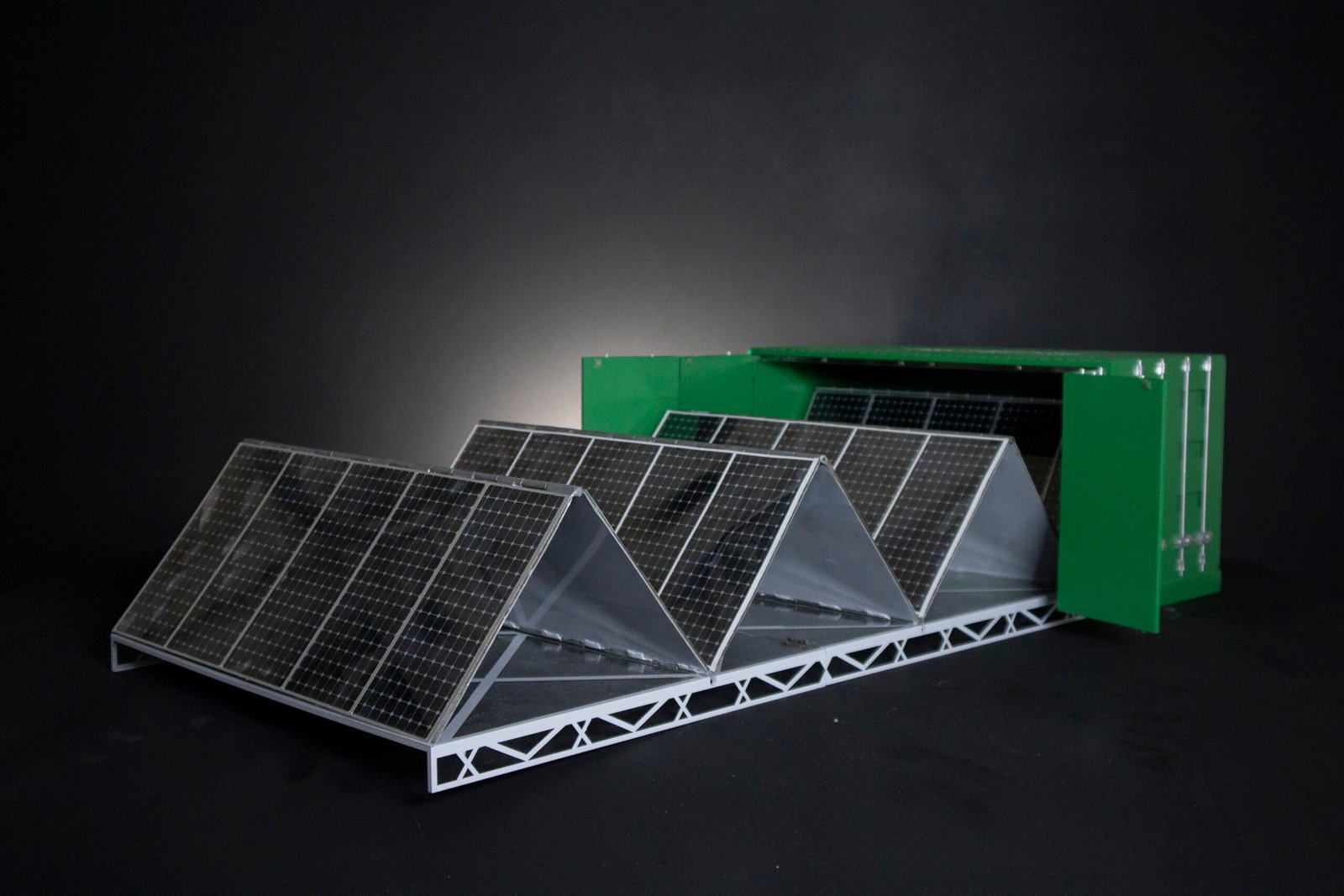

Metro Miniature Model / Engineering Scale Model / Structural Engineering Model

“Form ever follows function.” – Louis Sullivan

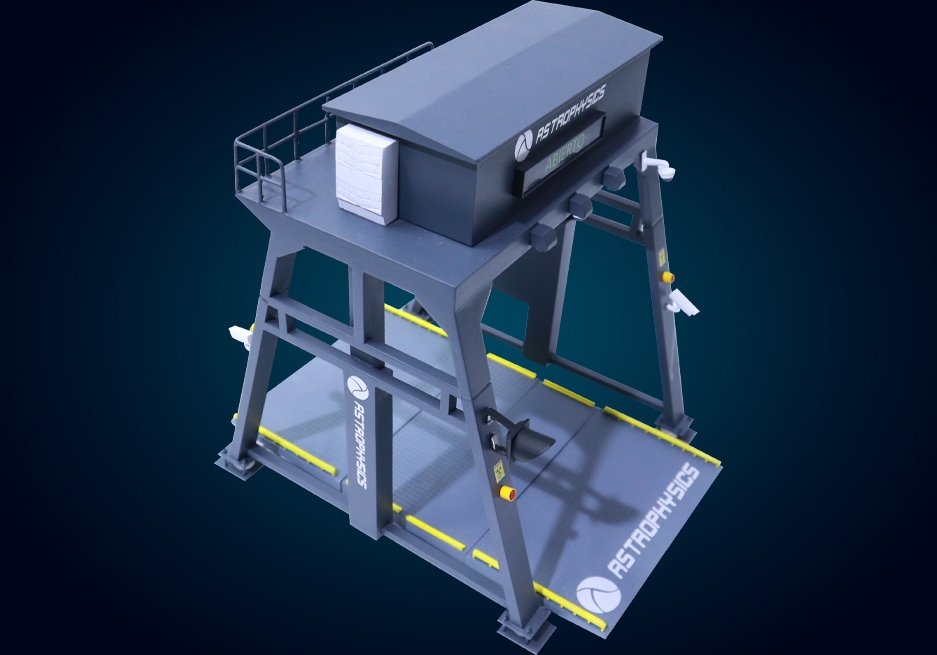

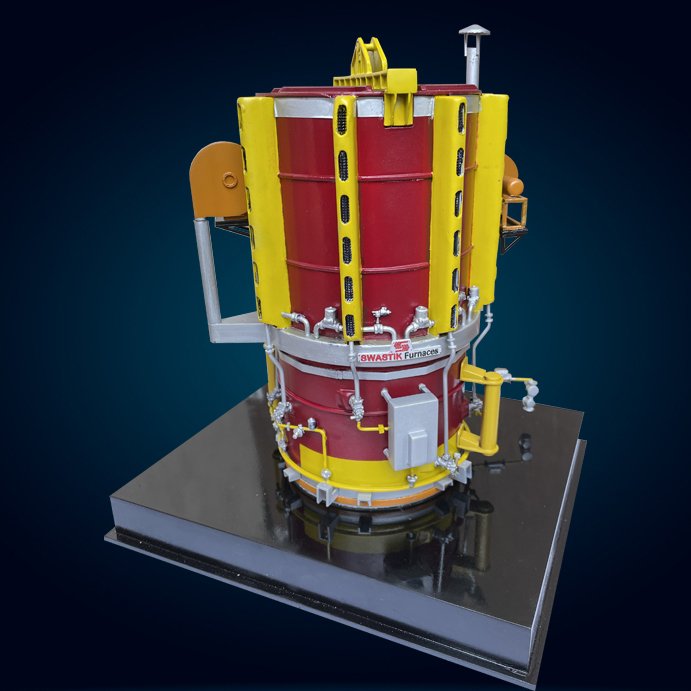

An Engineering model is a 3-dimensional representation of a highly complex industrial product, equipment, or structure design.

Engineering model-making is the process by which one makes a model of an idea, concept, or even an idea to be engineered. They assist the engineers and designers to model and simulate their designs before going to the manufacturing stage. You may consider them as intermediaries between an initial concept and a finished piece. As a result, the manufactured models help the engineers to comprehend different ideas, dealing with a tiny gadget or a wide construction.

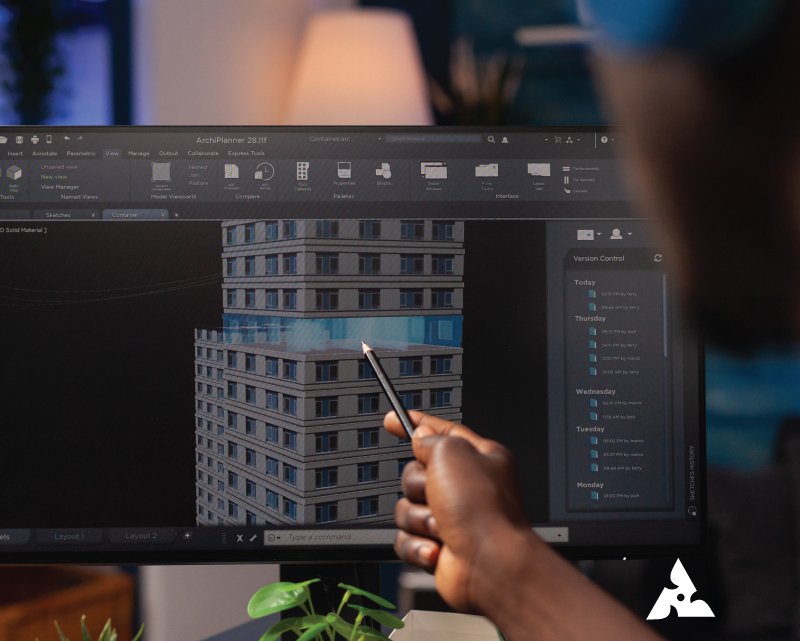

Such models can be as basic as scribbles on a piece of paper, digital models on an application, or intricate and lifelike prototypes. Working in teams, engineering model-making enables one to find out flaws and refine them from an idea that has been created into a tangible object.

Benefits of Engineering Model Making

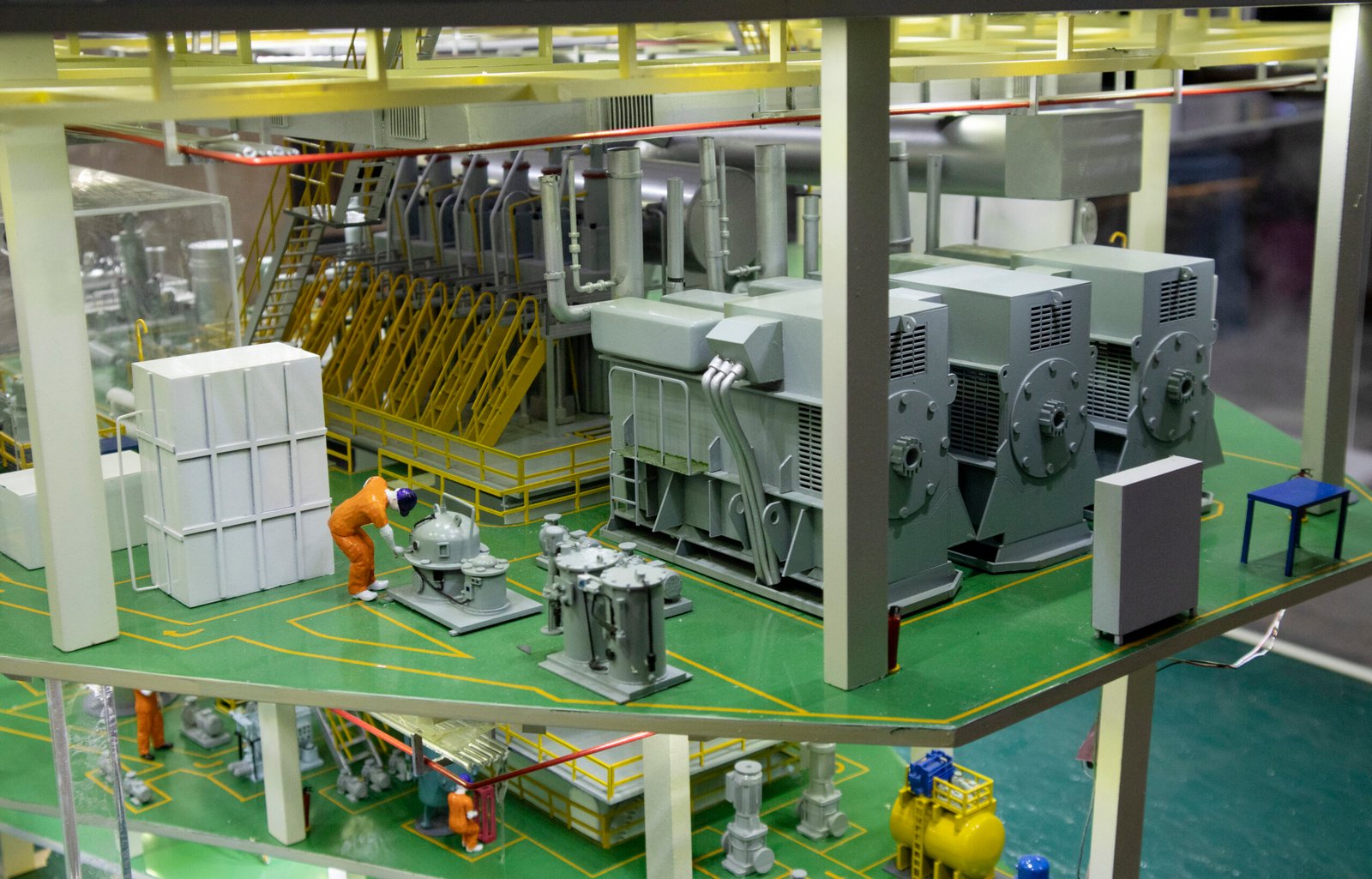

- Clearer Visualization: One of the biggest strengths of determining, designing, and creating an engineering model is that it allows all to visualize the design. Prototypes also enable one to visually see how the final design will appear or work, especially in the context of a team’s collaboration or when explaining the design to the client.

- Better Communication: That is the case when everyone is looking at the same model, which makes the discussion considerably easier. It can be possible that different teams can discuss the changes as well as the concerns with each other and avoid confusion and enhance the flow of work.

- Cost Savings: Innovative development before mass production can be useful to reduce expenditures. The benefits of catching problems early are that companies are able to prevent costly mistakes down the road. This forward-thinking strategy can therefore earn numerous positive outcomes in the future.

- Prototyping and Testing: Ideas must be tested, and one of the ways of achieving this is through the use of models. It enables teams to get a feel of how the design is going to operate in real life, which requires some modifications to make sure that the final product is fully compliant with the necessary standards. This type of approach is important in order to come up with dependable products.

- Reduced Risk: It is easy to use engineering models to model how a certain design will work. This makes it possible for engineers to identify problems that may be recurrent if there was actual production, especially in sensitive industries such as aerospace and automobile industries.

- Market Readiness: It is also important to note that models can be used as marketing strategies. A good model has a marketing appeal as it makes potential clients or investors take interest in a product before the real product is developed fully.

FAQ's

If this is your first time seeking an engineering scale model-making service, you likely have some questions. Read on to learn more!

A scale model in engineering is a physical or digital representation of an object, structure, or system that is reduced or enlarged according to a specific scale ratio. These models are used to visualize, analyze, and test engineering designs before full-scale production. By accurately replicating the dimensions and proportions of the original, scale models help engineers understand the functionality, performance, and potential issues of their designs. They are essential tools in fields like civil, mechanical, and aerospace engineering, enabling effective communication, planning, and problem-solving throughout the design and development process.

Models can be created with plastics and metals, as well as functional files to be printed through three-dimensional printing. The decision comes from knowing what the model is expected to achieve.

The amount of time it takes to make the model can vary. It is clear that an easy model may be created within a short span of time, whereas more intricate models could take time to develop to perfection.

Yes! It plays an important role in the automotive, aerospace, architectural, and consumer products industries as well. Both industries benefit from the certainty afforded by these models.

Definitely! We at Maadhu Creatives strive to deliver the precise engineering model for our clients according to their specifications for the final design.

Getting started is easy! You simply need to visit our website, and our welcoming staff will assist you in the process of transforming your engineering concepts into reality.

LET'S CONNECT !!!

Contact Maadhu creatives & We’re here to help you grow your business.