Discover the Magic of 3D Printing: FDM, DLP, and SLA Explained with Maadhu Creatives

Table of Contents

In the world of manufacture and designs, 3D printing has been identified as an innovation that revolutionizes how new products are produced. This cutting-edge technology enables the generation of objects that have depth and thickness from digital models in an added-up process, adding more layers. Fused Deposition Modeling (FDM), Digital Light Processing (DLP), and Stereolithography (SLA) are among the most common methods to achieve 3D printing among all those available methods. They all have their different advantages and uses. In this blog, we will look at these three 3D technologies in detail, discuss how they can be helpful, and higher we present the case of why Maadhu Creatives is the best 3D printing service in India.

Understanding 3D Printing Technologies

3D additive manufacturing, also commonly referred to as 3D printing, involves the use of a construction technique that deposits material in layers to form an object. This technique is quite different from those of conventional manufacturing processes, where material is removed from an initial workpiece block to produce the final desired shape. So let’s try to delve deeper into FDM, DLP, and SLA technologies to define what kind of distinctions they have and what advantages can be listed for each of them.

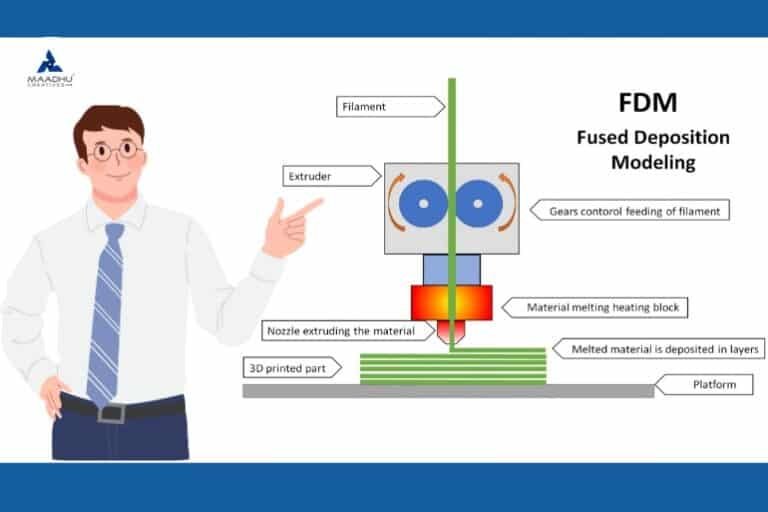

Fused Deposition Modeling (FDM)

What is FDM?

Fused Deposition Modeling (FDM) is a form of additive manufacturing that creates objects by thermoplastically extruding a polymer material. The ink of the printer deposits melted plastic in thin layers at a time, depending on the design of the object to be produced. This process may be considered similar to the superimposition of thin layers of matter to build up a full 3-dimensional object. Thanks to low cost and easy navigability, FDM is suitable for both raw learners and experts in the sphere.

Key Advantages of FDM:

- Cost-Effective: Concerning the choice of material used in the FDM printer, different materials used in FDM have been relatively cheaper as per other 3D printing methods. This makes FDM cheap to use, especially in instances where you have set yourself a low budget to work with.

- Wide Material Selection: Common filaments suitable to use with FDM are PLA, ABS, PETG, and TPU. Each of these materials carries some properties and can therefore be used in different ways.

- Durability: Because parts are built in a layer on a layer process by FDM, the final parts are stiff and serve well as functional prototype parts and end-use applications.

- Ease of Use: They are easy to use and assemble and therefore can be used at home, schools, and any business entities.

Common Uses of FDM:

- Rapid Prototyping: FDM is another method used, especially in the production of a large number of models, to test the feasibility of the design and functionality of the product before the actual manufacturing process.

- Functional Parts: For this reason, FDM is ideal for making tools and parts of machinery that will undergo stress when in use.

- Custom and Small-Batch Production: It can be ideal in the case of part products that are established in small quantities or specialties since the FDM allows for the customization of products that can be made in small quantities.

- Educational Projects and DIY Crafts: As mentioned above, FDM is the simplest type of 3D printing that is affordable and easy to use, and that is why it is most often applied in educational and DIY projects to teach 3D printing to learners.

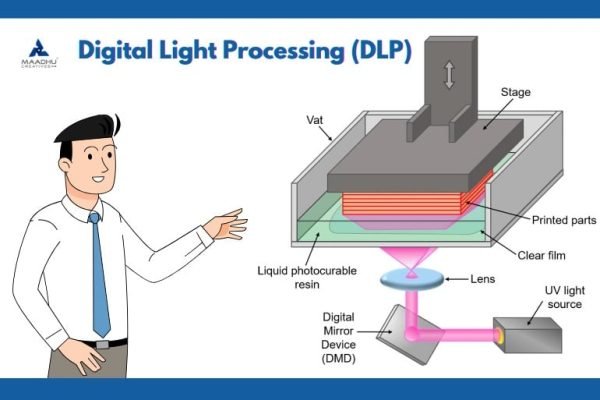

Digital Light Processing (DLP)

What is DLP?

DLP (Digital Light Processing) is one of the 3D printing technologies that uses a digital light projector to convert liquid resin into solid layers. In DLP, a projector projects light on a pot of resin and through ultras violet light, which cures the resin layer by layer in its according design. DLP is valued for its fine resolution and the ability to create images rapidly; it is effective for use in applications where tight presentation is necessary.

Key Advantages of DLP:

- High Resolution: DLP printers make it possible to achieve a very high resolution and are preferred for designs that involve complex shapes or small features on the designs.

- Fast Printing Speed: DLP, however, can cure an entire layer of resin at once and hence makes the whole process of printing much faster as compared to other technologies.

- Smooth Surface Finish: As it has been mentioned earlier, DLP produces very accurate and refined surfaces, which in most of the cases do not require further polishing.

- Versatility: DLP printers can work with numerous kinds of resins, and flexible and high temperature among them.

Common Uses of DLP:

- Jewelry Design: Due to its high resolution, DLP is specifically useful when modeling complicated and complicated jewelry creations, highlighting every detail.

- Dental and Orthodontic Models: This method is employed in generating accurate dental and also orthodontic models for fittings and treatment purposes so that fits may be done appropriately.

- Miniatures and Figurines: Thus, the accuracy of DLP is suitable for creating realistic models and models of toys and miniatures with intricate designs.

- High-Detail Prototypes: In the case where high details need to be produced and accurately done, DLP will offer the kind of accuracy that will produce the expected results.

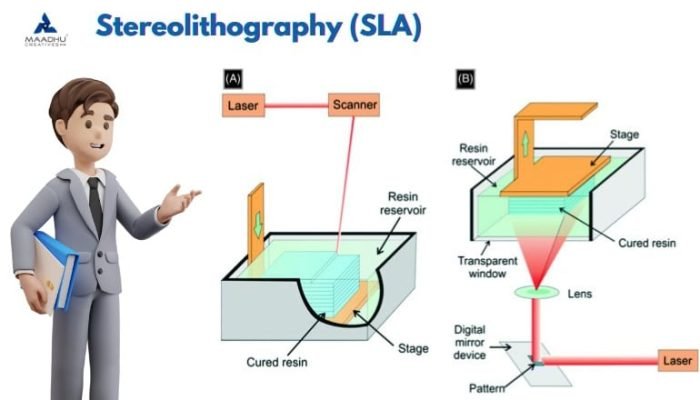

Stereolithography (SLA)

What is SLA?

Stereolithography (SLA) is one of the first techniques of 3D printing that has been developed. It uses a laser to harden the liquid resin in which the object is formed; the structure is built in a layer-by-layer manner. SLA is highly regarded for yielding high accuracy and complex geometries with fine surfaces. It has been of immense help in the evolution of 3D printing technology.

Key Advantages of SLA:

- Precision and Accuracy: SLA printers afford the end product sharp and detailed prints that can closely match the exact dimensions, hence useful for applications that need light precision.

- Complex Geometries: The proposed SLA technology enables the production of parts with high accuracy that can present complicated geometries compared with other fabrication technology.

- Smooth Finishes: Laser curing in SLA produces a high-quality surface finish that many of the products produced using the method hardly require further refining.

- Material Variety: Modern SLA wheels provide support for a number of resins with distinctive characteristics such as high strength and flexibility or biocompatibility.

Common Uses of SLA:

- Detailed Prototypes: The SLA produces models with intricate surface detail and high surface finish, enabling detailed testing and analyzing of designs.

- Functional Testing: SLA’s accuracy enables it to be used in functional testing with regard to parts and components to meet certain standards.

- Medical Models: SLA helps to develop accurate models for modeling medical structures to be used for surgeries, training, or teaching purposes.

- Artistic and Design Objects: Because of the detailed and intricate shape that it applies, SLA is often used in artistic and designing projects that need higher creativity.

Why Choose Maadhu Creatives for 3D Printing?

Exceptional Expertise

The special selling proposition of Maadhu Creatives is one’s expertise and wealth of knowledge in the sphere of 3D printing. Having experienced professionals integral to our team, clients can be sure that we implement FDM, DLP, as well as SLA technologies, and each project in the company is performed in the best-optimized way. Whether it is a newly developed prototype, a product manufactured in-house in accordance with a design created especially for you, or a technically demanding model, your project is guaranteed the best professional handling.

Cutting-Edge Technology

As for Maadhu Creatives, we guarantee to adopt the most innovative technologies in 3D printing as a company. We have an array of FDM, DLP, and SLA printers, thus ensuring that we are in a position to produce accurate and quality models. Due to the use of modern tools in our firm, we are in a position to handle a variety of tasks that may include simple work or even complex work in the form of detailed work with a lot of detail with simple high precision and accuracy.

Personalized Solutions

We are aware that every project is exclusive in its manner, and therefore, our solutions are in accordance with your peculiarities. For instance, if you require quick results to develop a concept, high-quality first shots for part detail, or functional prototype parts, we establish exactly personalized services to meet your goals. This means that we shall offer you the best solutions that best suit your needs in any of your 3D printing projects.

Competitive Pricing

And we at Maadhu Creatives try to stick to reasonable prices without compromising on the quality of our services. We offer fairly standard prices for our 3D printing services to make advanced technology available to individuals and businesses of all kinds. We want to provide the maximum value of the money you invest in us and get the best possible result.

High-Quality Output

That’s why we strive for excellence to provide our clients with the best outcome on every desired project. Maadhu Creatives ensures that all their prints are produced and done by professional people using high-quality material and equipment. Thanks to this commitment to delivering high-quality results, we guarantee that your project will be completed with the utmost attention to detail.

Full Support Every Step of the Way

At Maadhu Creatives, we’re here to help you from start to finish. Our friendly customer service team is always ready to answer your questions and solve any problems. We make sure your experience with our 3D printing services goes smoothly, providing clear guidance and support throughout your entire project.

Conclusion

With the help of 3D printers, technologies of designing and manufacturing have been revolutionized in such a way that they can be used for customization, higher efficiency, as well as innovations. FDM, DLP, and SLA are some of the most popular technologies that are used, but all of them have their own advantages, and that is why they are used to make different things. Maadhu Creatives occupation is in all three technologies, offering professional service, quality equipment, and tailor-made for 3D printing needs.

For the successful implementation of your 3D printing tasks, whether it is about coming up with a new prototype or creating precise models and usable parts, you’ve come to the right place with Maadhu Creatives, a company operating in India. We have vast experience, sophisticated equipment, and a lot of passion to give our best in every service that we offer. Further, learn how 3D printing can be useful for you and how the team at Maadhu Creatives can help turn your vision into reality.

FAQs About 3D printing

- FDM: A type of 3D printing process whereby objects are built up in layers from melt depostion of plastics called filaments. : Some of the most important aspects are fairly affordable pricing for its products, and the passion for achieving the perfect non-GUI designs.

- DLP: It also uses Digital projector for setting resin and it possesses dependable image resolution and faster printing speed.

SLA: In thermosetting, a liquid resin with the help of laser and this process has a very high degree of accuracy and can make clones of complex formations.

All these detailed views should be represented with DLP and SLA since both these techniques are much more precise and can depict even some of the smallest details.

Yes, FDM is indeed capable for parts as well as functional elements for such application where only a few numbers of pieces are required for manufacturing at a time only.

The DLP technology molds the whole layer at a time on to the material making the process faster than most of the other processes. Therefore, just as for the overall timewise approach to the construction process, it also depends upon the object’s size and Sophistication.

SLA prints usually have a smooth surface, but some additional finishing, like sanding or painting, might be needed to achieve the final look you want.