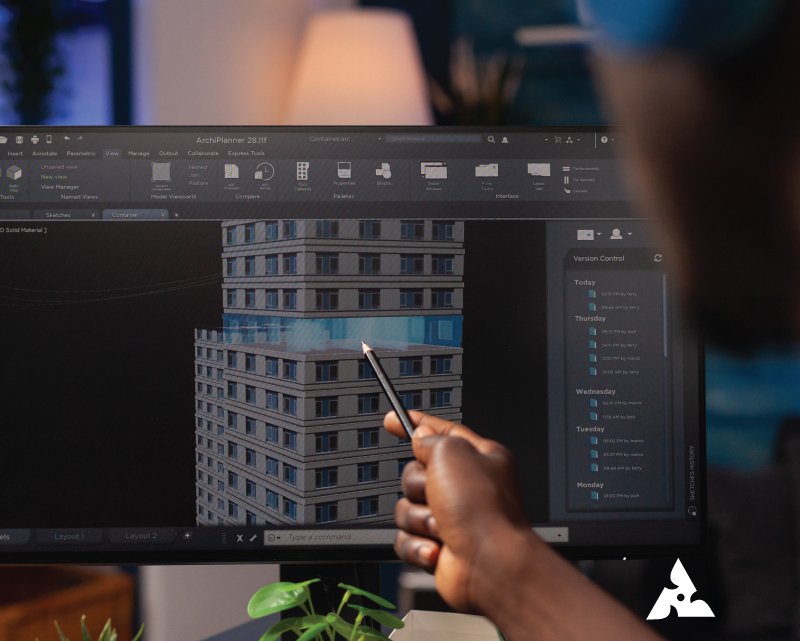

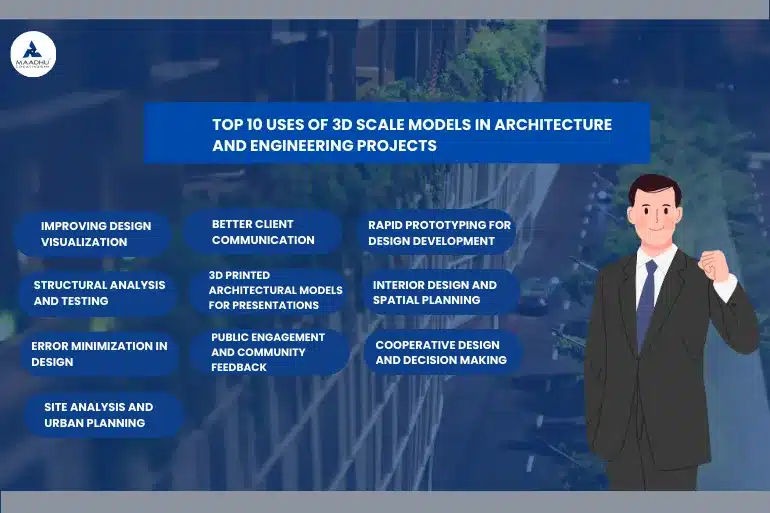

The Impact of Scale Models on Urban Planning and Development Table of Contents Let’s Connect Planning for urban areas is a complicated area that requires a keen focus on detail and a clear plan for how cities will develop in the near future. A key and efficient method used in this process is using scale models. They play an essential function in analyzing, visualizing, and refining urban development projects. This blog post examines the effects of model scale on city planning and development, focusing on their importance in making sustainable, efficient, and visually appealing urban spaces. What are Scale Models in Urban Planning? Models of scale in urban planning are digital or physical depictions of city areas that are reduced in size but still maintain exact proportions. They provide an actual way of visualizing the layout of cities, infrastructure, and the proposed development. Architectural scale models act as an intermediary between abstract planning concepts and practical applications, allowing architects, planners, and other stakeholders to better comprehend and communicate the intricate urban design. Benefits of Using Scale Models in Urban Planning 1. Enhanced Visualization Urban planning models provide an immersive three-dimensional view which makes it simpler to understand the overall layout and style of a town or development project. This enhanced visualization assists people in understanding spatial connections as well as the placement of infrastructure and the integration of many elements of the urban infrastructure. 2. Improved Communication and Collaboration Scale models allow for efficient communication between architects, urban planners officials from the government, as well as the general public. They function as an effective reference point for all parties, permitting all stakeholders to participate in a discussion that is informed and offer important input. This type of collaboration makes sure that the final master plan for urban planning is a reflection of the collective goals and requirements of the people. 3. Accurate Planning and Analysis Urban city models allow accurate planning as well as analysis of city areas. Through examining the scale models, planners can pinpoint potential issues like traffic congestion, insufficient green spaces, or a poor alignment of infrastructure. These findings allow for changes to be made prior the time construction starts, which can save time and money. 4. Public Engagement and Education Scale models play an essential role in involving the public in making complex urban planning concepts understandable to those who are not experts. They aid the public in understanding proposed changes and assess the impact they have on the community. This helps build confidence and encourages involvement in the process of planning. Applications of Scale Models in Urban Development 1. Master Plan Urban Planning Scale models are a crucial tool for creating and refining master plans. They offer a complete overview of the development proposed which includes the transportation network, zoning, as well as public facilities. Urban planning models to ensure the plan’s coherent and in line with the city’s goals for the long term. 2. Urban Development Visualization Visualization of urban development using scale models allows people to visualize the potential effects of new developments on the urban landscape. This tool helps to assess the viability and desirableness of new developments, while ensuring that they fit in with the existing character of the city and meet the requirements of the city’s residents. 3. Urban Infrastructure Models The scale models for city infrastructures, such as bridges, roads and utilities, offer an in-depth understanding of how these components interact with each other in the urban setting. These models assist planners in optimizing the design of infrastructures, increasing performance and reducing the chance of future issues. 4. Urban Design Scale Models Scale models for urban designs concentrate on the aesthetic as well as functional aspects of urban areas. They let designers experiment with different layouts, construction locations, and landscaping choices. This leads to more creative and imaginative urban designs that increase the quality of life for the residents. Technological Advancements in Scale Modeling 1. 3D Models for Urban Planning The introduction in 3D model technology is revolutionizing the way that scale modeling is done in urban development. Digital 3D models give you more flexibility, which allows for simple adjustments and precise simulations. They can also be integrated into Geographic Information Systems (GIS) to give you even greater insight into urban design and planning. 2. Virtual Reality (VR) and Augmented Reality (AR) Virtual real-time and augmented reality technology are becoming increasingly commonplace for urban design. It allows people to fully immerse themselves into the model of urban life, examining possible developments in a highly realistic and interactive way. The immersive experience helps improve understanding and aids in better decision-making. Case Studies: Impact of Scale Models on Urban Projects 1. Dubai THOE Masterplan model It is the Dubai THOE Masterplan Model designed by Maadhu Creatives, exemplifies the positive impact on urban design using scale models. The intricate model offers an accurate representation of the masterplan that is proposed with a focus on its layout and infrastructure and the most important features of the project. Through the use of advanced methods of modeling scale, Maadhu Creatives enabled stakeholders to understand the project’s scope and its potential impact in the landscape of urbanization. 2. World Miniature Model by Maadhu Creatives Maadhu Creatives crafted an intricate World Miniature Model, showcasing their skills in precise scale modeling. This project was an extremely precise and stunning representation of the world’s landscapes, landmarks, and other terrains. The model was used as an interactive and educational tool that gave viewers an entirely new perspective of the world’s geography as well as its cultural diversity. Challenges and Limitations 1. High Cost and Resource Intensity Making physically scaled models is costly and time-consuming, particularly for complex and large urban projects. Digital models, though cost-effective, require specialist software and experience. 2. Limitations in Representing Dynamic Changes Scale models, especially physical ones, might struggle to accurately represent dynamic changes, like traffic flow, environmental impact and population growth. Virtual models as well as simulations may solve this problem, but they require