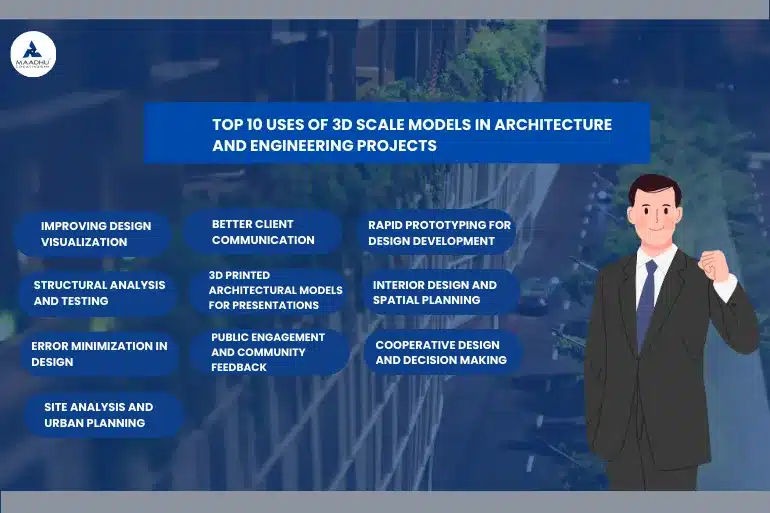

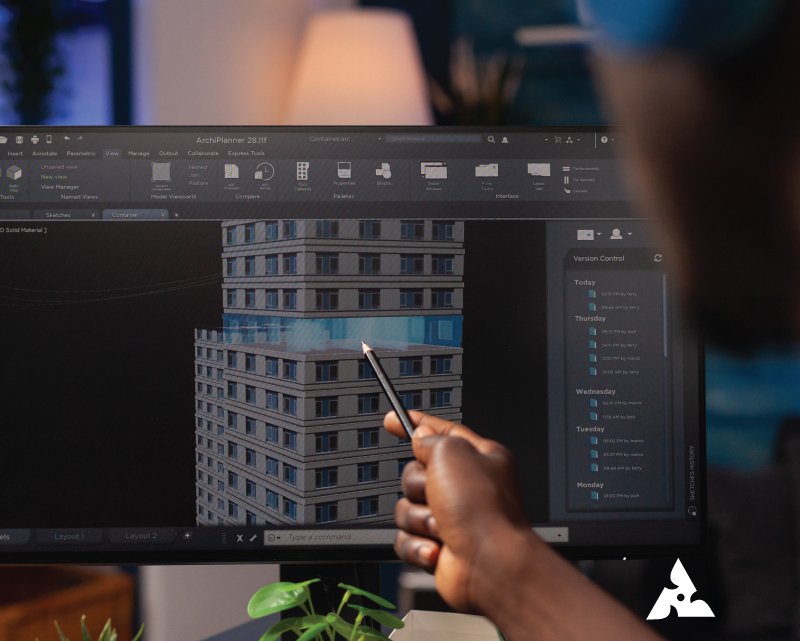

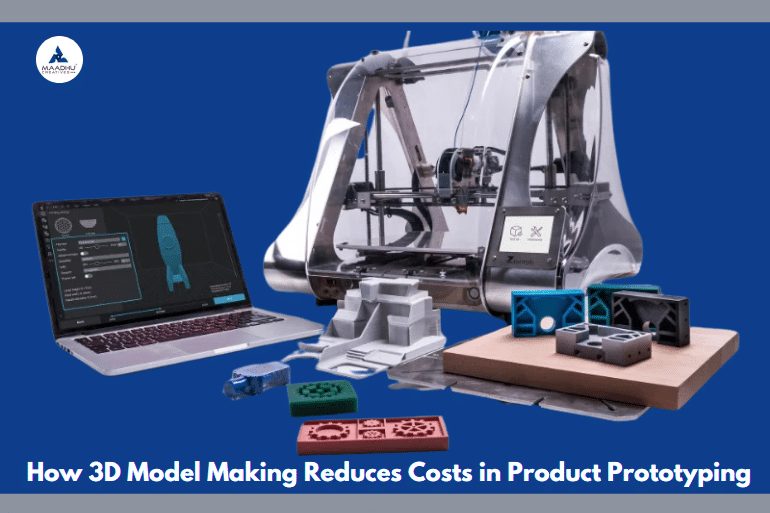

Top 10 Uses of 3D Scale Models in Architecture and Engineering Projects Table of Contents Let’s Connect 3D-scale models have radically changed the streams of architecture and engineering in recent years. The technology of 3D printing made model making faster and extremely precise. It introduced a new dimension wherein architects and engineers envision and present designs. Architectural models and applications of engineering models that have been 3D printed are now used to play a vital role in improving the design process, enhancing communication with clients, and optimizing project development. In this blog, we focus on the top 10 uses of 3D scale models in architectural and engineering projects, compare some traditional model-making methods with modern 3D technologies, and review the numerous benefits these models afford in design, communication, and problem-solving. What Are 3D Scale Models? Before getting into practical applications, it should be understood what 3D scale models are. The model is a replica of structures, designs, or concepts in real life, which is generated using 3D printing technology. With CAD software, architects and engineers start developing an accurate, scale model of a proposed project, and then a special 3D printer is used for printing. The material will depend on finish and durability: plastic, resin, or metal can be used. Because 3D printing scale models can be more accurate and iterative compared to the handcrafted models with a higher frequency of application, they are very useful both in design and for presentation. Precision and Detail: The Power of 3D Printing for Scale Models First and foremost, it is through 3D printing of scale models that will possibly allow an extremely high level of detail and precision. In contrast to this scenario, in traditional model-making, inconsistencies and imperfections would have resulted from handcrafting based on the workers’s expertise. In the case of 3D printing, on the other hand, every detail, from the smallest details to complex geometries, is under control. For example, if architects design 3D-printed miniatures, they can really ensure that every little detail, from the windows to roof structures, is repeated with rather accurate precision. This would also be about the ability to produce very complex and intricate shapes in terms of texture that might prove impossible or hard to create by hand. For instance, in the film industry, highly detailed miniatures for video games and other media require 3D printing as an inevitable tool that cannot be done without. The designers can create miniature models of characters and other vehicles or even settings according to original designs with a touch of realism never before seen. Top 10 Uses of 3D Scale Models in Architecture and Engineering Projects 1. Improving Design Visualization One of the most important advantages of 3D scale models is their ability to facilitate design visualization. Often, a use of 2D drawings has resulted in greater abstraction and lesser understanding for those who are not technically savvy at reading technical drawings. As such, the architectural model printed in 3D brings the work into an arena where people can relate to it physically. Example: stakeholders are better placed to understand the spatial relationships, proportions, and general design of a 3D-printed model of a building to reach better decisions 2. Better Client Communication Any architectural or engineering project is significantly communicated through client communication. 3D scale models thus ensure that all parties involved are on the same page. Clients can simply interact with a physical model, giving more precise feedback and even inputting design details. Such a model becomes an embodied representation of abstract ideas, therefore making it easier to discuss such design elements as textures and materials as well as scale. Example: A 3D printed model can allow a client to “walk through” a model of a building, giving the client a much more immersive experience than digital renderings alone. 3. Rapid Prototyping for Design Development One of the main benefits of 3D printed scale models is that they can create rapid prototypes. Designing is an iterative process, and 3D printing also allows architects and engineers to rapidly prototype and test ideas that can be fine-tuned in real time. This saves time and resources compared to the traditional model-making practice, which generally starts over from scratch with each iteration in revision. Example: An architect may use the 3D printing technology and produce various versions of the building facade with several eases and then change them within a short duration until he gets the design he wants. 4. Structural Analysis and Testing These three-dimensional scale models are very important in engineering designs to check the structural integrity of a particular design. Engineers are able to perform stress or load tests, simulating many realistic testing conditions through actual models. This may save expensive mistakes later on in the construction process. Example: The engineers can make a 3D model of a bridge or structural supports, print it, and test the load-carrying capabilities before full-scale building. 5. Site Analysis and Urban Planning Site analysis and urban planning require 3D scale models. An architect and city planner can study how the proposed structure fits into the setting through its use. This would include sunlight, wind patterns, traffic flow, and pedestrian accessibility. The possibility to change a model allows a designer to look at the spaces around them. Example: A 3D printed model of an urban plan has enabled city planners to see how a new building will impact the existing structures and public places. 6. Architectural Models for Presentations Using 3D Printing During presentations to clients, investors, or stakeholders, 3D printing allows for designing powerful visual aids when showing architectural models. People get to understand the design better by making presentations more intriguing and livelier. This is because what 3D-printed architectural models offer is far removed from static 2D drawings or digital images, hence adding some form of realism to presentations. Example: A concept of commercial development can be showcased during the presentation to the investors using a 3D printed model, thereby raising funds. 7. Interior Design and Spatial Planning 3D