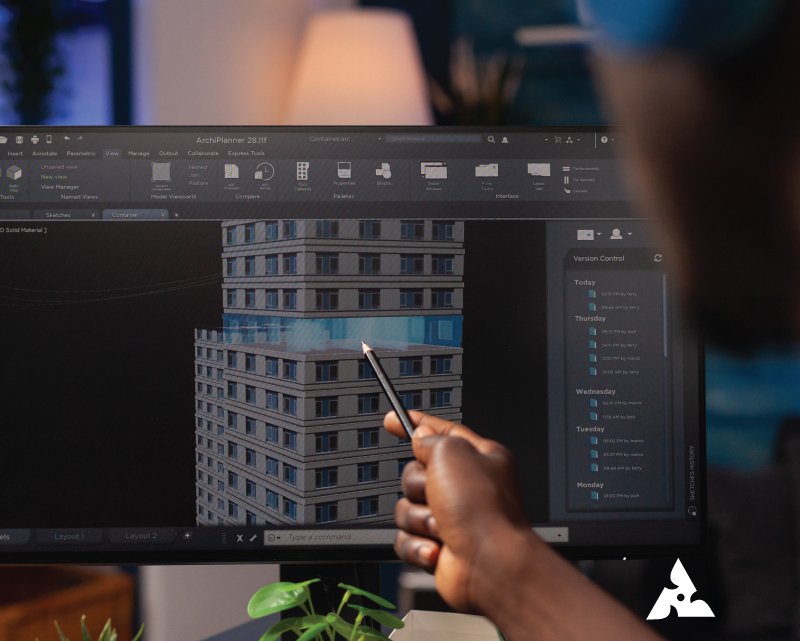

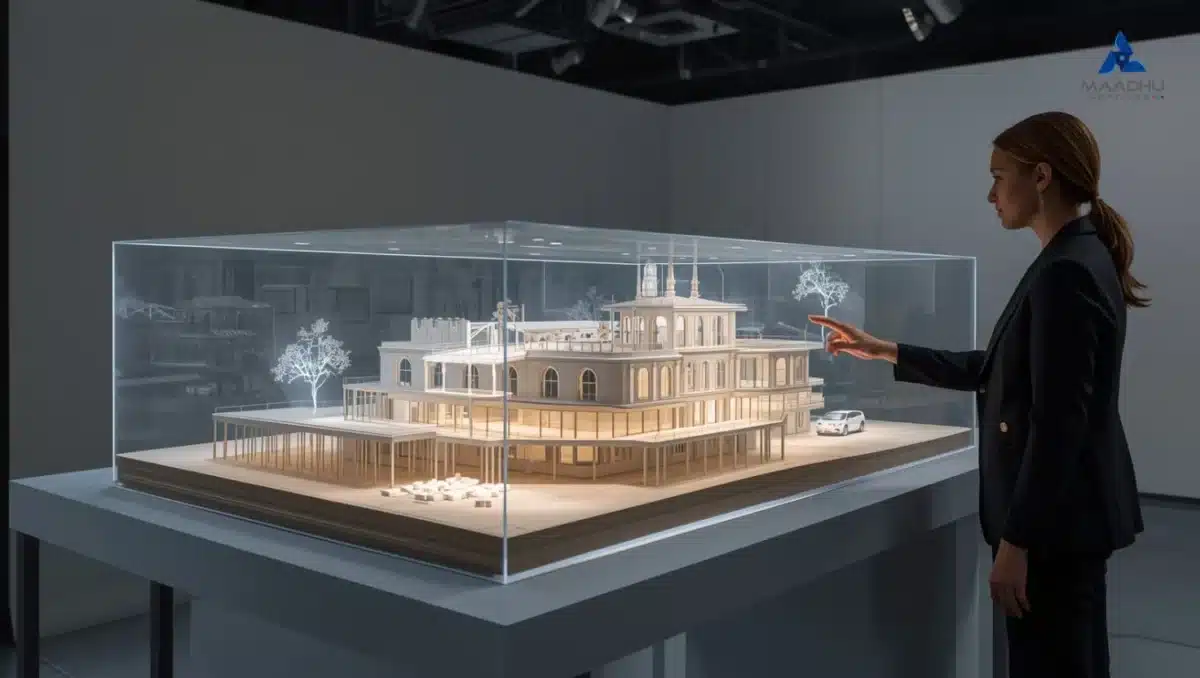

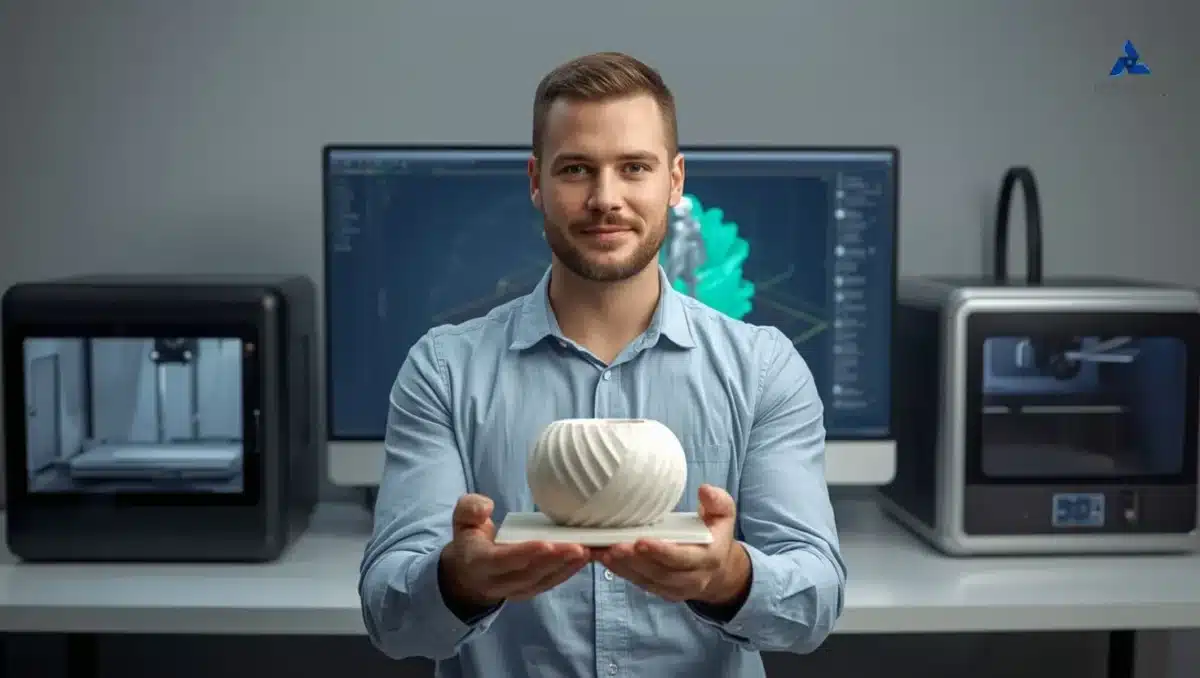

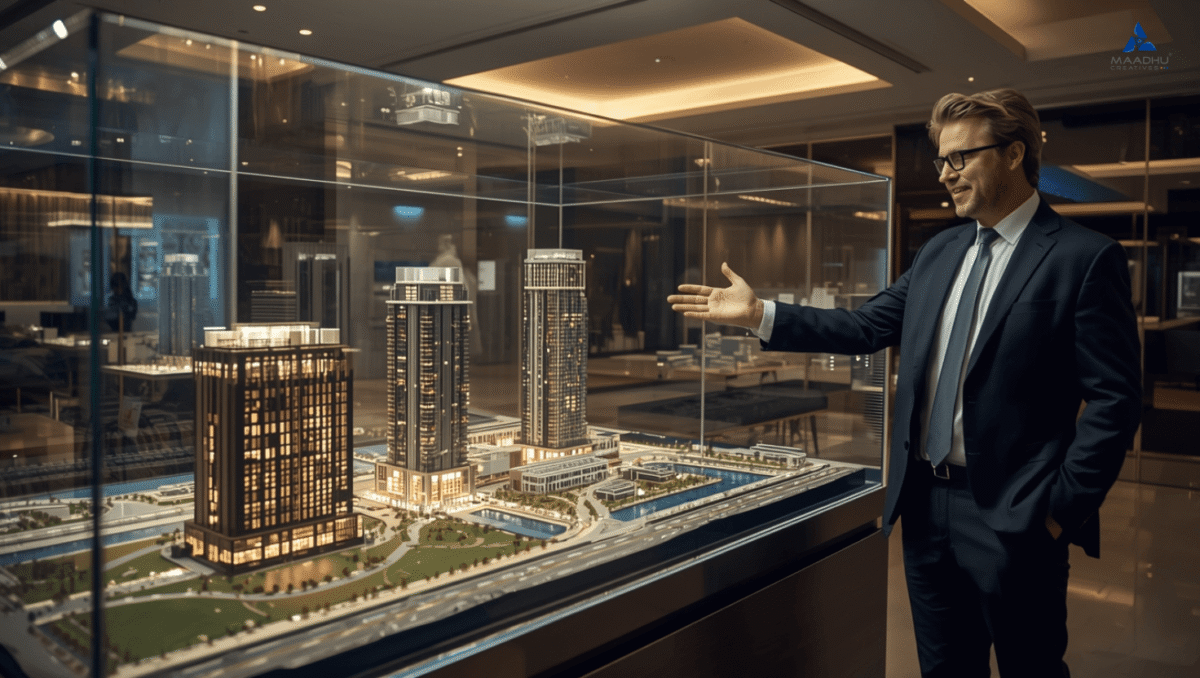

3D building design is revolutionizing architecture and construction by enhancing accuracy, reducing errors, and improving project visualization. Through BIM modeling, 3D walkthroughs, and advanced architectural rendering, architects, engineers, and clients can collaborate efficiently and make informed decisions before construction begins.