FDM 3D Printing

FDM 3D Printing

What is FDM 3D Printing?

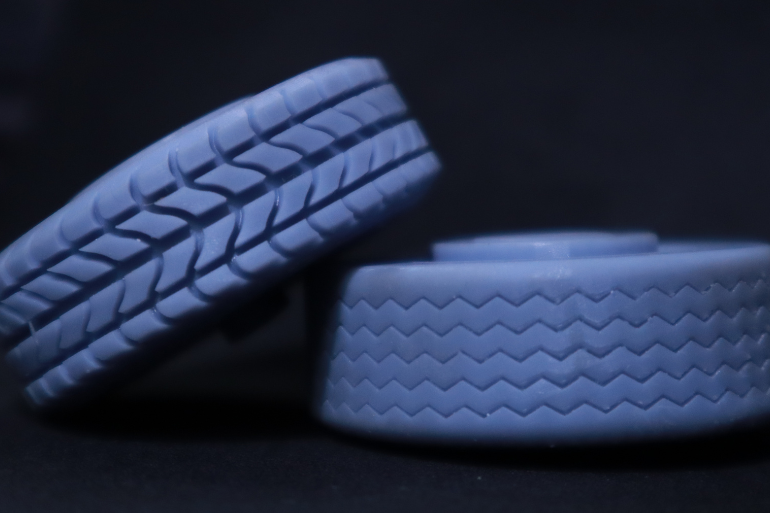

FDM is another one of the most common techniques of addiction and operates by using thermoplastic to fabricate a three-dimensional object based on layer by layer. Its process works as it melts the plastic filament, then extrudes the melted plastic to form a structure. At this stage, when it is hot, the melted plastic comes out while starting to cool down, it forms layers of the desired object on the core.

On account of its real, functional, and correct models, FDM is used in many industries, for instance, aerospace industries, automotive industries, and even health care industries. In fact, it’s one of the most cost-effective and least complex types of 3D printing, thus thoroughly applied by enthusiasts as well as expert sectors.

Benefits of FDM 3D Printing

- Cost-Effective: Generally speaking, FDM printers are less expensive than other 3D printer types. This is why such machines are practical for companies and people who care about their wallets. The parts like PLA and ABS are also not expensive.

- Variety of Materials: FDM printing supports the use of various plastics like PLA, ABS, PETG, and others. This implies that you can choose and use materials according to their requirements, be it rigidity, resilience, or heat resistance.

- Easy to Use: Printers based on the FDM technology are generally very easy to use, and so even the novice has little trouble using them. Most have intuitive handles and software that is user-friendly to make it easier for you to concentrate on the designs rather than learning how to use the computer.

- Quick Prototyping: This getting stuck in layer by layer approach offered by FDM ensures that prototyping is done in the comfort of sufficient time. Models can also be designed and tested in a short duration that helps in reducing the time taken from the deriving of the idea to the product.

- Durable Prints: Fused deposition molded (FDM) objects have high dimensional strength and are wear and tear resistant. This is useful for components that are to be used repeatedly or under stress.

- Eco-Friendly Options: Even PLA that many people choose to use is an FDM material that features biodegradability. This makes this method of printing relatively eco-friendly than others.

FAQ's

If this is your first time seeking an FDM 3d Printing service, you likely have some questions. Read on to learn more!

The printing time can vary. Small devices could possibly take only a few hours, even as large ones must take a day or more.

Yes, many FDM printers can deal with large items, but the length they may print depends upon the precise printer model.

Definitely! Many industries depend on FDM-posted components for beneficial uses because, in reality, they are long-lasting and dependable.

LET'S CONNECT !!!

Contact Maadhu creatives & We’re here to help you grow your business.