Product Prototype Model Making

Product Prototype Model Makers / Miniature Product Prototype Model Makers / Product Prototype Scale Models

Your Premier Block Model Making Company

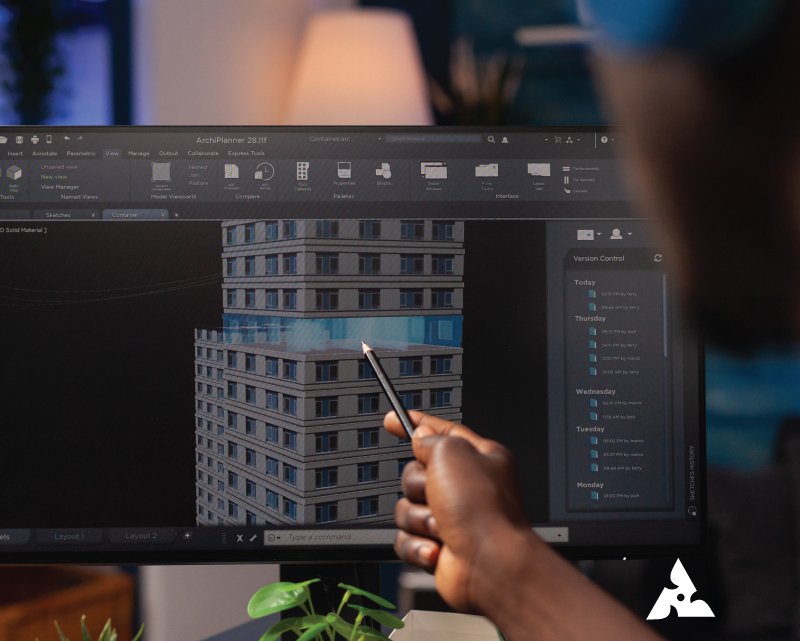

Our mission is to bring your ideas to life through meticulously crafted product prototype miniature models.

physical expression of the design and makes it possible for the creators to study the concept that is presented in their minds even before creating the product on a larger scale. Subjected to the product as well as its development, prototypes are fashioned out of materials like plastic, wood, or even metal.

A prototype enables the designer and engineer to determine the potential problems and flaws through building, testing functionality, and obtaining input. Whether it is a new electronic device, piece of furniture, or toy, prototypes enable every participant to see, touch, and feel the idea. It is an important experience in the process of refining designs so that the final product meets users needs effectively.

Product Scale Model

Product Scale Model by Maadhu Creatives is a meticulously crafted miniature replica designed to precision. Whether for architectural prototypes, product demonstrations, or marketing presentations, each model is expertly crafted to capture intricate details and convey the essence of the original product.

Benefits of Product Prototype Model Making

- Better Visualization: Prototypes allow teams to visually realize their ideas, or else in a more tangible manner they can very easily communicate concepts to stakeholders and clients. It is particularly handy for people who may have difficulty understanding abstract designs.

- Testing and Feedback: Perhaps a significant positive of prototype making is the chance for functional testing. People can use the prototyping to experiment and provide significant feedback. Immediate feedback can translate into enhancements that will make the final product much better.

- Cost Effectiveness: The expenditure on a prototype will serve to save more money. Issues are caught early on in the design process before mass production, which saves very costly mistakes. Any adjustment made to the prototype is so much cheaper compared to making an adjustment to a finished product.

- Improved Design: This process of prototyping is actually an activator of innovation and creativity. Designers can test alternatives and make refinements based on the result of testing and, therefore, may invent better products, which are also more friendlier to users in the end.

- Pre-Commercation Readiness: A prototype allows businesses to anticipate market interest before launching a product into the market. That will allow the company to show the prototypes to its potential customers, investors, or partners and may make them highly enthusiastic, thus securing funding.

- Informed Decision Making: The prototypes help bring out critical information to inform future decisions. With the real models, teams can discuss and brainstorm ideas of change and improvement.

FAQ's Product Prototype model

If this is your first time seeking an Product Prototype scale model-making service, you likely have some questions. Read on to learn more!

Product models and prototypes are physical representations of a product concept or design. They can be used to visualize, test, and refine the product before it’s manufactured.

- Model: A general term for a physical representation of an object or system.

- Prototype: A functional or non-functional model of a product, often used for testing and evaluation.

The process of making a prototype depends on the product’s complexity and the desired level of detail. Here’s a general overview:

- Conceptualization: Develop a clear understanding of the product’s design and functionality.

- Material Selection: Choose materials that mimic the properties of the final product.

- Construction: Assemble the prototype using techniques like 3D printing, CNC machining, or manual fabrication.

- Testing and Refinement: Evaluate the prototype for functionality, aesthetics, and user experience. Make necessary adjustments.

A scale model prototype is a smaller version of the intended product. It’s often used for architectural models, engineering designs, and product concepts. The scale is determined by the desired level of detail and the purpose of the model.

The cost of making a prototype varies significantly depending on factors such as:

- Complexity of the design: More intricate designs require more time and materials.

- Materials used: High-quality materials can increase costs.

- Manufacturing methods: 3D printing or CNC machining can be more expensive than manual fabrication.

- Level of detail: Detailed prototypes require more precision and craftsmanship.

Prototypes serve several purposes:

- Visualization: They help stakeholders visualize the product and its features.

- Testing: Prototypes can be used to test functionality, ergonomics, and user experience.

- Feedback: They can gather feedback from users and make necessary improvements.

- Manufacturing planning: Prototypes can aid in planning manufacturing processes and tooling.

- Marketing: They can be used for marketing and promotional purposes.

Plastics, wood, metal, and foam are such materials from which a prototype can be prepared. It would be chosen depending on whether it is for the product or for a certain stage of its production.

The time taken in creating a prototype will depend on the sophistication of the prototype. Some simple models may take less than a week to be produced, while in some cases a week is too short for a complex design.

Yes, many people will produce their prototype by themselves using either a 3D printer or just hands to produce it. However, in a more complex product, a professional service will likely do the job better.

Draw out your product idea and detail what you will be able to achieve from your prototype. Then, determine if you will be making the prototype or using a service professional for it.

Contact Us

Contact Maadhu creatives & We’re here to help you grow your business.