3D Printing in the Medical Industry: Revolutionizing Healthcare Solutions

Table of Contents

The medical field has witnessed such advancements with time, and one of the most thrilling inventions introduced was 3D printing. It has changed how we approach healthcare by working in solutions: personal, efficient, and more accessible. In this blog, we are going to see the history of 3D printing of medicine, its pros and cons, materials used here, future possibilities, and much more.

A Brief History of 3D Printing in the Medical Industry

Actually, the term 3D printing or additive manufacturing dates back to the 1980s, but health care utilization of it only took place in the 2000s. The first critical use of 3D printing in medicine was for creating customized prosthetics and implants. Over time, scientists and medical professionals altered the technology for a wide array of applications in the health care fields.

The first organ was published for printing through a 3D printer in 2003. This gave way to further research into bioprinting. The creation of tissues and organs. Since then, 3D printing has been widely accepted in medicine. Today, the company can boast innovations with patient-specific surgical models, dental implants, and even bioprinted tissues.

Today, hospitals and clinics around the world utilize 3D printing for the improvement of patient outcomes and for process streamlining. The promise for the future indeed is that such research continues to be done to print whole organs that can be transplanted.

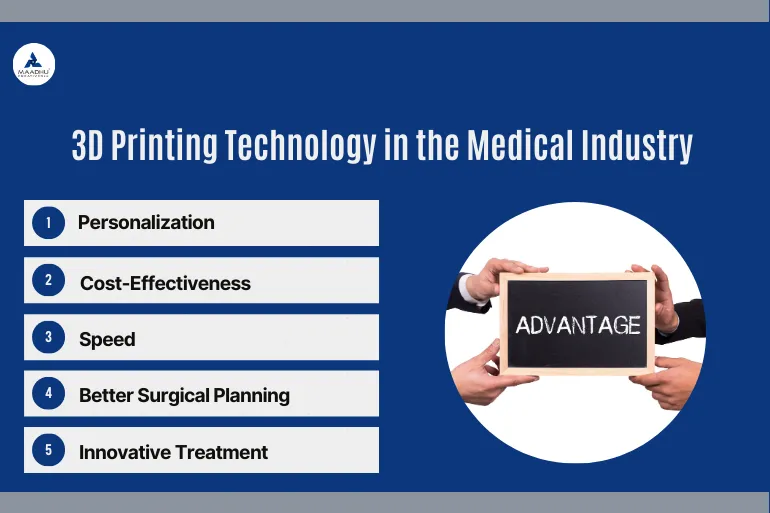

Advantages of 3D Printing Technology in the Medical Industry

1. Personalization

The most significant benefits of 3D printing lie in the customized solutions that are possible with its help. The patient is uniquely different; hence, made-to-measure implants, prosthetics, and surgical tools to fit every anatomy would be possible through 3D printing. Customization leads to better fitting, comfort, and functionality and increases patient satisfaction and outcomes in general.

2. Cost-Effectiveness

3D printing can therefore highly reduce the cost in the medical sector. The conventional methods of production might have come out as quite expensive and highly time-consuming. On the other hand, 3D printing entails the immediate production of what is required and not required to produce much in terms of inventory, hence resulting in less waste. Efficiency can therefore lead to reduced costs for health providers and for patients, besides making health care more accessible.

3. Speed

Time also plays a crucial role in emergencies. 3D printing can rapidly produce medical devices that are needed at the right time. Suppose a surgeon needs a certain device to be used in surgery, then it can be printed at the site instead of waiting for its delivery. This speed can literally save patients in time-sensitive situations.

4. Better Surgical Planning

Physicians can now use the 3D-printed anatomy of a patient to plan complex surgeries. These models are actual references with which the physicians understand the surgical site much better, thus exposing them to the procedure before going into the operation room.

5. Innovative Treatment

With 3D printing, it has opened the possibilities of treatments previously thought impossible. For instance, researchers are still experimenting on bioprinting, where tissues that will eventually be used for drug testing or even transplanted organs are grown. This innovation may transform the treatment and resolution of diseases and injuries for patients everywhere.

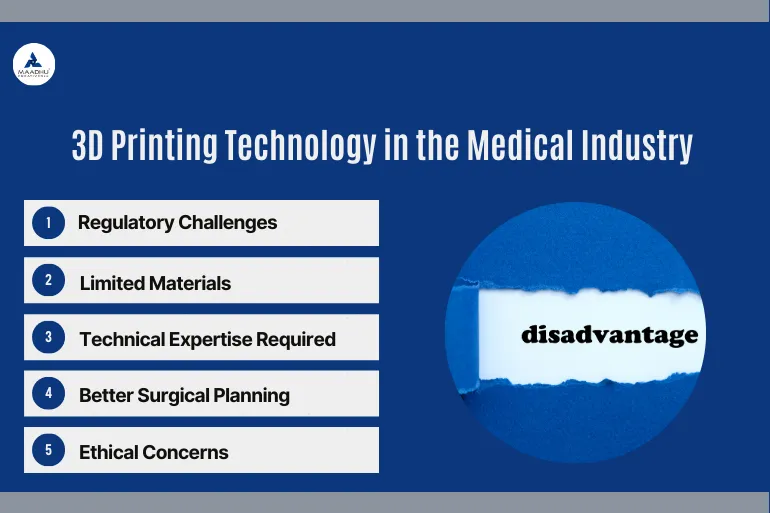

Disadvantages of 3D Printing Technology in the Medical Industry

1. Regulatory Challenges

Although 3D printing promises so much, it does come with its own challenges. For example, regulatory bodies, including the FDA of the United States, should make sure that a 3D-printed medical device is safe and effective. This type of bureaucracy and red tape can be complex and consume enormous amounts of time, which thus significantly slows down the adoption of new technologies.

2. Limited Materials

Compared with traditional manufacturing methods, 3D printing for medicinal purposes is still confined to limited types of materials. There are no appropriate biocompatible and application-specific materials available yet. This limitation can threaten the development of certain medical devices altogether.

3. Technical Expertise Required

The integration of 3D printing into healthcare demands a fair amount of knowledge and expertise. Not all the medical facilities have the means or the skills needed to implement such technology appropriately. This presents a gap in the accessibility of the real benefits from the use of 3D printing, as with the smaller clinics or hospitals that may not have advanced training.

4. Ethical Concerns

With each new technology, the ethical issues started coming forth. The potential application of technology in the printing of organs and tissues has raised many issues concerning organ transplantation and availability. Some of the discussions are therefore about equal access and preventing its misuse. Further, concern is raised on “designer organs” or even on how this technology may be exploited against vulnerable populations.

3D Printing Materials Used in the Medical Industry

1. Plastics

Plastics are among the most frequently used materials for 3D printing in medical applications. They are versatile, lightweight, and may be engineered to have certain properties. Among the most commonly used plastic materials are PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene) for models, surgical guides, and prosthetics. materials that are relatively cheap and work well.

2. Metals

The trend nowadays tends to be more and more towards metal 3D printing, especially concerning implant production and surgical equipment. Titanium and stainless steel are highly feasible materials due to their strength, durability, and ability to be biocompatible. Metal printing is most valuable for the creation of implants with a wide capability to integrate into the human body, thereby making it a better fit, which naturally improves patient outcomes.

3. Bioprinting Materials

Bioprinting is the creation of tissues and organs by using living cells. The whole process requires special materials that have been named bioinks by researchers, which are prepared from cells, growth factors, and hydrogels. Researchers find new bioinks every day that allow for improving functionality and viability of printed tissues and provide access to novel pathways in regenerative medicine.

4. Ceramics

For instance, they have been used in clinical conditions, including dentistry and bone fixing. Since they are biocompatible and stimulate the growth of bones, these materials present a better selection for most dental implants and surgeries that carry out the reconstruction process. Using ceramics in 3D printing is beneficial because the shapes that cannot be manufactured through the original methods can be obtained. Therefore, they are much more effective compared to earlier treatments.

Current Applications of 3D Printing in Healthcare

1. Prosthetics and Orthotics

3D printing altered the method of producing prosthetic limbs and orthotic devices. Custom prosthetics would have more individual anatomy fitting, and patients could be as comfortable as possible. Saves more money and reduces the waiting time for prosthetic limbs and orthotics.

2. Surgical Models

Surgeries can be planned and practiced very easily with 3D-printed models. Anatomical models could be visualized, and practice done before an actual event. With such preparation, success is most likely to occur, and the confidence of the surgeon is increased.

3. Dental Applications

Crowns, bridges, and dentures are printed using 3D printing in dental applications. Fast and accurate production of custom-fitted dental appliances results in a better patient experience and outcome.

4. Bioprinting Tissues

This could help in creating tissues, either for transplantation or for the repair of damaged portions. Such tissues or portions are enabled through this technological advancement in the field of medicine. Though yet at an experimental stage, bioprinting is being explored with the aim of printing fully functional tissues. Researchers are now finding ways to print skin, cartilage, and other tissue routes to organ regeneration.

5. Medical Devices

3D printing is applied in the production of several medical devices, including surgical tools and drug delivery systems, as well as educational models of anatomy. On-demand production enables researchers to innovate and adjust to individual clinical needs much faster.

The Future of 3D Printing in Healthcare

1. Personalized Medicine

Personalized medicine is still within the boundaries of technology. The advancements in 3D printing make it accessible, and personalizing medical devices and procedures regarding treatment according to specific patients would mostly be routine. This can develop healthier results and also lead to better allocation of medical resources.

2. Printing of Organs

Imagine if the dream of printing fully functional organs finally comes into reality. Through tough work, researchers are finding ways to create organs from the cells of a patient so as not to provoke the immune system and further reduce the problem of organ shortages.

3. Expansion to Remote Areas

3D printing could revolutionize access to health in remote or underserved areas. Communities will now be able to produce medical devices needed on-site and without having to wait for shipments or traveling long distances. Their health-related outcomes may, therefore, be improved and multiplied.

4. Collaboration and Innovation

The future of 3D printing in medicine would be a collaboration between engineers, medical professionals, and researchers. Together, they would explore new materials, develop innovative applications, and address challenges associated with this technology. Collaboration would spur breakthroughs in healthcare.

5. Education and Training

By applying 3D printing, the medical education and training can be taken to the next level, because here students will get the actual models in their hands for practicing, which will further allow the educators to adjust their teaching to increase hands-on experience. Consequently, more competent and confident healthcare professionals are expected to come out of this process.

FAQs

3D printing in medicine is the use of additive manufacturing technology for customized medical devices implants and prosthetics, including being able to print tissues and organs.

3D printing enables tailoring to unique patient needs that are made better by this technology by ensuring enhanced effectiveness of treatment, improved success rate of the surgery, and also a reduced length of recovery time.

The devices need to meet the regulatory requirements; otherwise, there is a risk. Also, the safety and efficacy of the 3D-printed devices will essentially depend on a number of factors for the sake of patient safety.

Researchers are now even trying to bioprint organs. However, this is still in the very early stages. In fact, the advancements at present are all for the development of tissues to be used for drug testing and research.